Product scale replication capacity is accelerated

Behind Baidu’s intelligent cloud’s advance into industry, it is inseparable from its many years of precipitation and accumulation in the industrial field.

In fact, over the past few years, the AI capabilities of Baidu’s intelligent cloud have gone from a single scene in the early days to more and more core scenes in the industry. “That’s what we’ve been doing and it’s a long-term goal.” According to Wu Xueyi, core scenarios such as quality control, process optimization, production safety, energy consumption optimization, and intelligent scheduling have always been the focus of Baidu Intelligent Cloud.

Focusing on these core scenarios, a series of benchmarking cases have been landed in a number of industries, so that many enterprises have seen real benefits.

Taking the Ji ‘nan second machine tool, known as the “eighteen arrohan of the national machine tool industry” as an example, the production scheduling link of the main control center of the leading enterprise of heavy CNC stamping equipment has long existed pain points. Manual scheduling is intense and time-consuming, and can not be optimized and adjusted in real time, which is not conducive to the production development of enterprises in the environment of great market changes.

After the introduction of Baidu intelligent Cloud’s AI intelligent scheduling optimization engine, the scheduling situation of Ji ‘nan second machine tool began to be significantly improved, and different workshops producing large, small and medium-sized products could be efficiently scheduled in the factory, and the production efficiency and product delivery efficiency of this machine tool company were significantly improved. Ji ‘nan Second machine tool has also created an intelligent safety production monitoring platform for a variety of complex scenarios, and the development efficiency of AI models has been increased by 30%, which means that enterprises can respond more quickly to emerging new risks.

In addition to enabling the production scheduling of the machine tool industry, the auxiliary transportation scheduling schemes they do in the mining industry and some process optimization schemes they provide in the chemical industry have gradually penetrated into the core scene of the industry.

This kind of play from the application of the core scene is related to Baidu’s concept of application first in the industrial field. However, it has also faced challenges, whether the same product can be copied to different enterprises, whether it can reduce customized redevelopment, determines the efficiency and coverage speed of Baidu’s intelligent cloud output AI capabilities.

The emergence of the industrial Internet platform has solved this problem to a certain extent.

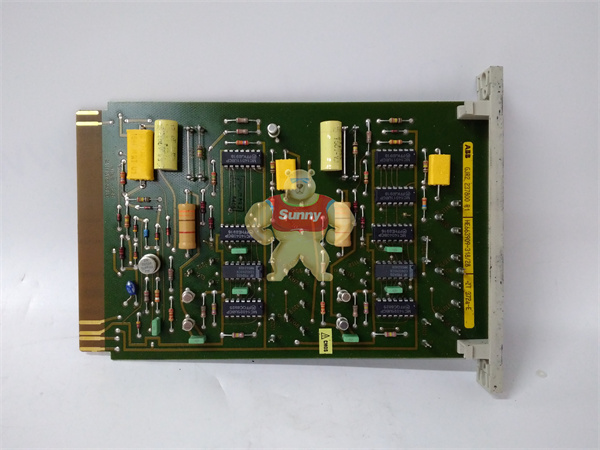

ZT372a-E GJR2237800R1 HE663909-31828

ZT372a-E GJR2237800R1 HE663909-31828

“Through the open platform, we have deposited the capabilities used in all the customers we have done, and extracted the common capabilities needed in different industries, and continue to do deep and thorough.” Wu Xueyi, for example, said that in the most common safety problems in industrial scenes, Baidu intelligent Cloud currently not only has a general visual model, but also has many capabilities specifically for some industry-specific scenes such as wearing no work clothes, wearing no hard hat, and whether there is a fire on the scene.

These capabilities, which have been continuously precipitated and polished, have gradually formed intelligent solutions that can be standardized and replicated on a large scale, not only reducing the threshold for enterprises to obtain AI capabilities, but also enabling Baidu Intelligent Cloud to achieve “intelligent” on-demand on many projects, no longer “building wheels from scratch”, and greatly improving the speed and cost of delivery.

For example, in view of the problem that the quality inspection fake points rate is too high in PCB printed circuit boards, Baidu Intelligent Cloud has formed an intelligent quality inspection solution that can filter 80% fake points, which can help enterprises save more than 2 million yuan in labor costs a year. At present, the solution has been used in many local enterprises such as mutual Electronics, Yangxuan Electronics and Shengyi Technology in Changshu, Suzhou.

The advantages of Baidu’s intelligent cloud in industry have also been enhanced and consolidated through the open object platform. Data show that since its release in May 2021, Baidu Intelligent cloud open matter has accumulated more than 200 industrial solutions and precipitated 38,000 industrial models. In the “double span” platform dynamic evaluation list released by the Ministry of Industry and Information Technology in June this year, Kaiwu ranked first in the list of Internet companies, and the ranking increased significantly compared with the first list last year.

A Baidu intelligent cloud veteran analysis, it is Baidu intelligent cloud in the past year the number of solutions and for the core scene cases increased significantly, for this dynamic evaluation added points.

At the same time, the scale replication capability of Baidu intelligent cloud not only stays at the level of product and technology replication, but also extends to the replication of general solutions and models. “For example, the expansion of our object base is already a replication of some models.” Wu Xueyi said.

It is reported that Baidu intelligent cloud Kaifu has been deeply grounded in 16 regions such as Suzhou, Guangzhou and Chongqing, and has built an “AI+ industrial Internet” industrial base in the local area, and its operations and services adhere to “in the park” and “around” to solve the problem of “the last kilometer” of digital application.

Industry insiders believe that the arrival of the large model will further accelerate the product scale replication ability of Baidu intelligent cloud.

“Some personalized needs used to be adjusted by engineers a little bit, but after the large model comes, the engineer has a very good assistant, and can give a lot of work to the large model to do, and then do further tuning according to its output results.” Mr. Hu added.

Compared with previous AI algorithms or small models, the large model has more data and parameters, and the generalization ability is stronger. This generalization ability allows more industrial scenarios to obtain technical dividends at a lower threshold and cost. According to reports, at present, Wenxin large model has the largest industrial application scale in China, with more than 300 ecological partners, and has achieved quite good test results in more than 400 scenarios.

The industry has observed that based on the large model ecology that is taking shape, Baidu intelligent Cloud will also upgrade the way it provides three layers of services to the industry in the future:

First of all, with the central state-owned enterprises and other large model application pioneer enterprises, from the enterprise’s research and development, design, production, operation and marketing and other links, to find can stand the test of practice, with replicable large model application scenarios, covering safety production, intelligent logistics, AI quality inspection and other fields, to help enterprises reduce costs and increase efficiency and innovation.

Secondly, based on the Wenxin Qianfan large model platform, the whole process tool chain of the large model is provided, and the AI platform products such as Baidu AI large base and Kaiwu Industrial Internet are superimposed to reduce the threshold for enterprises to obtain AI capabilities.

Finally, to create a timely response to customer needs of the engineer team and the local industrial ecology, the Wenxin Qianfan large model platform and the corresponding computing power platform sinking, to solve the large model and AI application of the last mile problem.

1 Year Warranty

1 Year Warranty