Recently, Johnson Controls officially released Metasys 12.0 Building automation system. Since the Metasys system was introduced in 1990, Johnson Controls has continuously optimized and upgraded the Metasys system to keep pace with the development trend of cutting-edge technology and the evolution of building functions. Compared to the previous version, Metasys 12.0 has been upgraded in four aspects: network security, data exchange, troubleshooting, and user interface, bringing users a highly secure, future-oriented system network, as well as a clear modernization and upgrade path to fully realize the value of building management system investment.

Johnson Controls Metasys 12.0 Continuously optimizes building operations and management efficiency through four major upgrades

Upgrade interoperability standards to ensure network security

Metasys 12.0 uses the BACnet Secure Connect (BACnet/SC) open source protocol, an upgrade of the BACnet interoperability standard designed to improve network security and the integrity of network infrastructure. Metasys 12.0 complies with the BACnet/SC interoperability standard to maintain the latest information technology security protocols.

BACnet/SC is used in multiple components of Metasys 12.0. Compliance with the BACnet/SC protocol allows Metasys 12.0 to easily integrate with multiple systems and devices and achieve a higher level of network security while complying with the latest information technology security and infrastructure protocols.

New MQTT driver for easy data exchange with iot platform

In the era of the Internet of Things (IoT), the Internet of Things technology promotes the development of smart buildings. MQTT is a lightweight transport protocol developed specifically for the Internet of Things, which is lightweight, simple, open and easy to implement, and can provide reliable messaging services for iot devices in low bandwidth and unstable network environments.

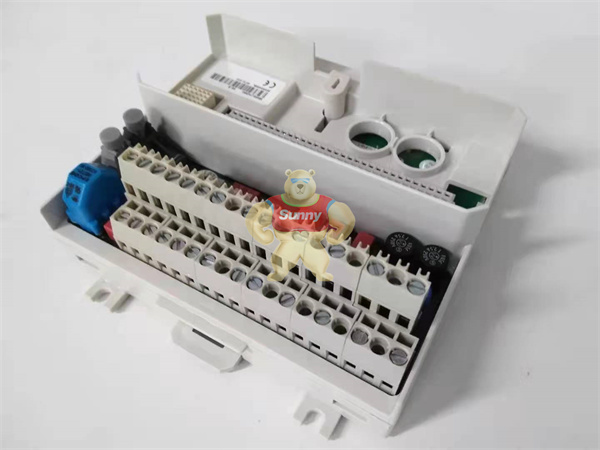

3BSE017427R1 NBIO-21CU

3BSE017427R1 NBIO-21CU

Metasys 12.0 adds a new MQTT driver to the SNE and SNC family of network engines. The MQTT driver supports two-way communication between the network engine and the common MQTT agent, enabling data exchange between Metasys systems and mainstream iot platforms and applications.

Equipped with a new generation of equipment controllers, easy to quickly troubleshoot nearby

In Metasys 12.0, the modern family of device controllers first released based on Metasys 10.0 has been expanded with the addition of two new CG series universal application controllers with an onboard 2.4-inch color display and navigation keyboard, and a 3.5-inch color remote loadable display.

The onboard display and the remotely mountable display serve as a local interface to the controller of the CG series device, making it easy for users to perform mission-critical tasks. For example, when monitoring the value and status of the point, viewing the alarm information and trend, adjusting the set point and forcing the output value, the technical personnel can quickly troubleshoot and resume operation when viewing the mechanical equipment, and no longer need to operate through the machine room.

Enhanced user interface functions, better support SMP user upgrade

The system’s user interface has been enhanced in Metasys 12.0 to include some of the views and features familiar to users of SMP (Field Management Portal), including a new logical viewer and editor, view navigation, customized summaries, and system object configuration views. Metasys 12.0 provides clear user interface migration and modernization options to support users with older SMPS to upgrade to the latest user interface.

User interface enhancements also include system activities, graphical enhancements, and timelines. In addition, Metasys 12.0 includes improvements to API monitoring and commands, and support for registration of numeric changes, greatly reducing the need for applications that use the API to constantly poll data.

With more than 130 years of experience, Johnson Controls is committed to using smart building technology and advanced building automation systems to improve the safety and efficiency of building operations and ensure the comfort of building users. Having been deeply engaged in the local market for many years, Johnson Controls’ development direction is highly consistent with China’s sustainable development goals, and will continue to actively build green and low-carbon intelligent buildings through continuous innovation of products and solutions to help the sustainable development of China’s construction industry.

1 Year Warranty

1 Year Warranty