In the product development process, good ideas often fall short if they are not supported by the right components. When a PCB is connected to another PCB, data, power and signals are like the line of life, but it is difficult to find an integrated connector on the market to meet the connection needs of so many signal types. Although customized solutions can solve this problem, they take too long, the minimum order is too high, and it is difficult to prototype. Harting’s har-modular® connectors are tailored for specific applications, with a wide range of modules that can be configured online to provide an almost limitless range of personalized solutions.

Create a dedicated connection scheme in three steps

With har-modular® online configurator, users can quickly and easily find a personalized solution to meet their needs, and all envisioned combinations can be configured in three simple steps.

Step 1: Select the module and quantity

The har-modular® online configurator provides modules for three signal types, power, signal and data. The first step is to select the right modules and quantity for the application.

Signal module

There are two modules available for signal transmission

9 contacts, maximum current 2A/ contact

1 coaxial contact, 50 ohms or 75 ohms

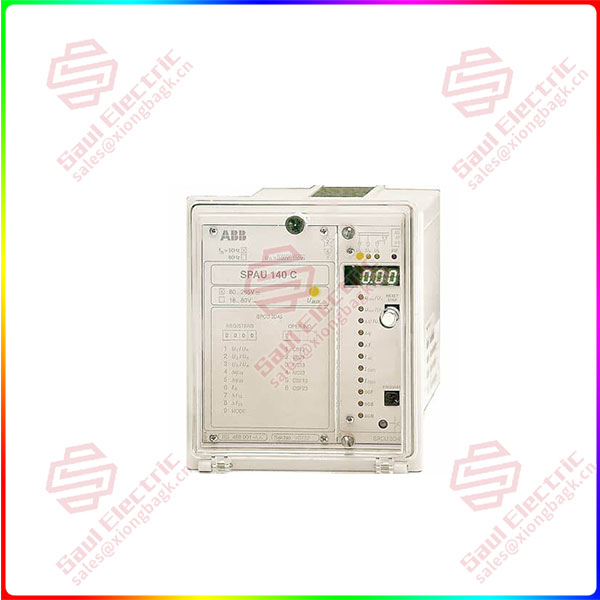

SPAU140C

Power module

There are three modules available for power transmission

1 contact, the maximum current is 40A/ contact;

3 contacts, the maximum current is 15A/ contact;

4 contacts, maximum current 6A/ contact.High voltage module

There is a module for transmitting high voltage

1 contact, up to 2800V, 1.5A

Step 2: Select guide needle material and location

For a secure and reliable connection between modules, each har-modular® connector requires two guide pins. Users can freely choose metal or plastic guide pins according to actual needs. The best position for the guide pin is the end of the connector, which can be flexibly adjusted according to the application scenario.

Step 3: Determine the length of the fixed guide rail

To ensure that the modules are aligned with the fixed guide rails, place the modules side by side using the installation tool, and adjust the length of the yellow fixed guide rails to be equal to the total length of all modules. As for the male or female head of the connecting module facing up, it depends on the specific situation. Then, press the top edge of the mounting bar into the top slot of the module. Start from one end, connect a module at the same time, and perform the same operation on the other end.

1 Year Warranty

1 Year Warranty