As a pillar industry of the real economy, China’s manufacturing industry has a long history and a huge industrial structure. Numerous industrial chain links and high complexity are typical characteristics of the supply chain of manufacturing enterprises, and the road to promote the digital transformation of the supply chain has become a common choice for high-quality development of enterprises. Through decision-making optimization of intelligent supply chain planning, manufacturing enterprises can establish a more efficient lean production planning model and a corresponding organizational structure, effectively reduce inventory, improve the efficiency of the entire supply chain planning and optimize the planning results, and further achieve multiple goals such as lean production, rational inventory and personnel optimization.

In order to help manufacturing enterprises build a better supply chain base in the “VUCA (Uka) era” to smoothly pass through the cycle of transformation and development, Shanshu Technology launched a decision optimization product – Shanshu Platform (LibraMind) for industrial intelligent manufacturing in March this year, and scientifically develop short and medium term production plans for enterprises. Optimize production management and operation processes to improve the flexibility and agility of the entire supply chain to adapt to rapidly changing market demands. Recently, e-works reporter conducted an interview with Huang Xiang, vice president and general manager of Industrial line Division of Sanshu Digital Technology, to understand the role of intelligent decision making in supply chain optimization, the key technologies of intelligent decision making and the core characteristics of digital game platform. In Huang Xiang’s view, high-level supply chain management has always been one of the core competitiveness of manufacturing enterprises. Under the tide of digitalization, enterprise supply chain is evolving in the direction of faster demand response, higher collaborative efficiency and more open data. The application of intelligent decision technology based on operation optimization and machine learning will accelerate the reconstruction of supply chain. Become the focus and foothold to improve the level of enterprise supply chain.

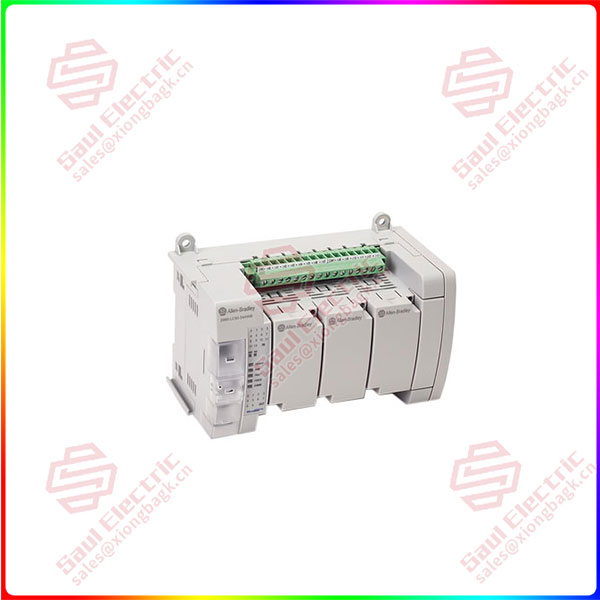

2080-LC50-24AWB

Comprehensive intelligence, belongs to the genetic evolution of supply chain

With the development of intelligent manufacturing in full swing and the accelerated integration of online and offline, the supply chain system in which manufacturing enterprises rely on inventory to fight sales and game the price difference with dealers and suppliers has become a thing of the past. Huang Xiang said that with the participation of manufacturers, suppliers, customers and other parties, supply chain management has become increasingly complex. Especially for large and group enterprises, the industrial chain and supply chain reconstruction is developing in the direction of regionalization, and the relationship between upstream and downstream is becoming closer. Cultivating self-oriented industrial chain is an important strategic opportunity for manufacturing enterprises.

The famous American economist Christopher once said: “There are only supply chains in the market without enterprises.” Now, the real competition is no longer between companies, but between supply chains.” In Huang Xiang’s view, supply chain management has gradually become an obvious “core engine” from the “invisible hand” that holds the direction of the enterprise, mainly due to the following two reasons:

First of all, it is the “recessive gene” that has always existed in the domestic manufacturing industry but has not been well presented and valued: Huang Xiang said that China, as the world’s second largest economy and the world’s first manufacturing country, has a complete and large-scale industrial system, strong production capacity and perfect supporting capacity. In the era of digital economy, enterprise supply chain is no longer a single “chain” like line, but a “network” like structure, each system and each role are connected and interdependent. For example, when auto parts manufacturers complete a production and marketing activity, they not only need to ensure the efficient operation of the internal production line, such as production decision-making, workshop operation, inventory logistics, but also need to cooperate with the external seamless link, such as upstream raw materials, parts suppliers, downstream Oems and dealers, logistics, consumers, etc., the interaction between the parties is becoming more and more close and frequent.

Secondly, it is the “dominant gene” injected into the development of enterprises by emerging technologies such as cloud computing, the Internet of Things, and artificial intelligence: according to the practical experience accumulated by Sanshu Technology, manufacturing enterprises are combining traditional supply chain management methods with digital technology to achieve efficient, intelligent and transparent the entire process of the supply chain. In particular, in the face of external uncertain supply environment and the diversification and segmentation of market demand, manufacturing enterprises are prompted to face the supply chain synergy driven by real-time customer and consumer demand, and then form a flexible and personalized manufacturing closed-loop, and ultimately significantly shorten the delivery cycle.

1 Year Warranty

1 Year Warranty