On August 15, 2023, Lenovo Venture Capital’s invested enterprise, motion control product supplier Gu High-tech Co., LTD. (hereinafter referred to as: Gu High-tech), was officially listed on the GEM of Shenzhen Stock Exchange, stock abbreviation: Gu High-tech, stock code is 301510, the issue price is 12 yuan/share, the opening price is 75 yuan/share, up 525%. As one of the first echelon suppliers of motion control in China, the funds raised by Gu High-tech will be used for the industrialization and digitalization of motion control systems, intelligent upgrading projects, and research and innovation projects of core motion control technologies.

01From the field of motion control

To win high-end intelligent manufacturing

Gu High-tech has a very high reputation in the field of robotics and motion control, because it is one of the few companies that have adhered to the core technology research and development of motion control and intelligent manufacturing for more than 20 years. Gu High-tech was founded in 1999 by Li Zexiang, Gao Bingqiang and Wu Hong, three internationally renowned scholars and experts in the field of robotics, microelectronics and motion control from Hong Kong University of Science and Technology. The company’s business scope includes the production and operation of motion controllers, electronic processing equipment, computer software and automation technology development, etc. It is the first high-tech enterprise in the Asia-Pacific region with independent intellectual property rights, specializing in the research and development of motion control and intelligent manufacturing core technology, and is also one of the integrated solution providers of fully connected intelligent manufacturing at home and abroad.

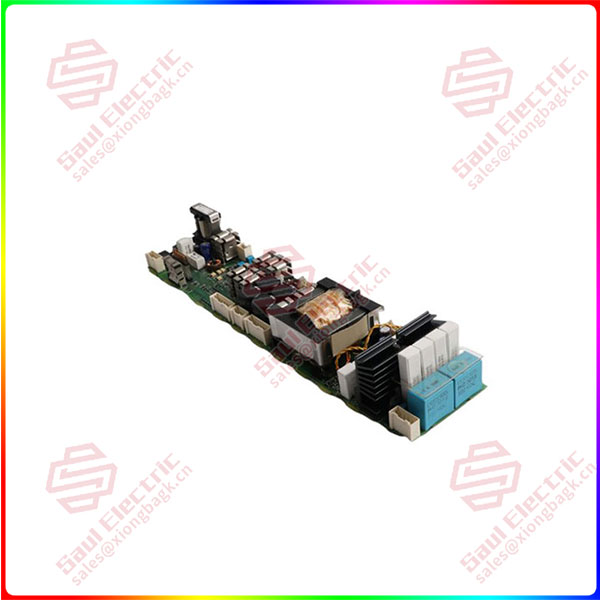

DSMB-01C

He Zhiqiang, senior vice president of Lenovo Group and president of Lenovo Group, said that Gu Gao ushered in the IPO and deserved the name. In China, a manufacturing country, intelligent manufacturing leads industrial upgrading is only a matter of time, but there are many difficulties in the subdivision field that need to be overcome, and motion control is one of them. Many scenes of industrial production rely on motion control related technologies to achieve the quality and efficiency of complex processes. In the context of intelligent manufacturing, it is also necessary to take into account the collaboration with robots, machine vision and other related technologies in order to achieve productivity upgrading. Gu high-tech has grasped the motion control as the core of industrial manufacturing, and can introduce solutions in line with multiple track users according to the specific pain points of control technology industrialization, greatly shortening the path of industrial upgrading. Lenovo Venture Capital continues to pay attention to the field of intelligent manufacturing, and the spirit of insisting on hard science and technology and adhering to industrialization is exactly what is needed for intelligent manufacturing this “competition road”.

Over the past 20 years, Gugao Technology has combined industry needs, extracted common difficulties in the industry, deeply developed technology and product research and development, fully integrated research and development advantages and global university resources, and provided the market with a series of open, reconfigurable, fully interconnected high-end equipment control and development platforms, helping system integrators and equipment manufacturers to help customers reduce the threshold of technology research and development. To achieve the goal of shortening the incubation cycle of products and realizing the industrialization of high-end equipment.

From the perspective of product and technical system, Gugao mainly takes high-performance network motion controller and servo driver as the core products, and develops China’s self-controllable multi-master-slave, peer-to-peer ring network, high-real-time industrial field network communication protocol around the products, and solves the “jam” problem of motion control technology from the underlying technology. It is regarded as a few high-end equipment manufacturing enterprises in China that master the key links of equipment manufacturing in the five directions of “perception, control, decision-making, execution and industrial interconnection”.

To date, we have deployed more than 600,000 sets of motion control systems for nearly 60 industries, more than 2,000 customers and more than 200 system integrators. The domestic marketing service network has spread to Beijing, Shanghai, Xi ‘an, Wuhan, Shenzhen and other major cities, the overseas market has extended to Southeast Asia, the Middle East and Europe and the United States about 30 countries and regions, become one of the high speed and high precision motion controller suppliers in the Chinese market.

1 Year Warranty

1 Year Warranty