Supply chain comprehensive cost reduction of more than 30%

In the second quarter, this supply chain full link digital service model has been applied in a number of large industrial enterprises, significantly improving the comprehensive cost of the supply chain of industrial enterprises. According to the research data of Jingdong Industry, by realizing the spare parts inventory “buy less and prepare less”, improving the performance delivery efficiency, and intelligent scheduling of warehouse allocation resources, enterprises can reduce the comprehensive cost of the supply chain by more than 30%.

For example, when serving Desheng Iron and Steel, the largest private steel enterprise in Sichuan Province, Jingdong Industry created spare parts supply chain solutions for it, which significantly reduced inventory costs. As a typical heavy industry, the spare parts inventory of steel mills is usually hundreds of millions, which will not only consume a lot of inventory resources, but also occupy a lot of working capital. The Jingdong Industrial spare parts supply chain solution will accurately analyze the number and times of various spare parts in the past two years, and give the average consumption of a replenishment cycle and suggested replenishment water level and replenishment cycle through artificial intelligence algorithms to help steel mills achieve inventory water level control based on spare parts demand prediction, so as to achieve “less spare, less buy, fast use and fast supply”. At present, Dessun Steel’s auxiliary spare parts and secondary spare parts, the two largest and highest proportion of spare parts management efficiency has been significantly improved, and spare parts inventory cost is expected to be reduced by 20%.

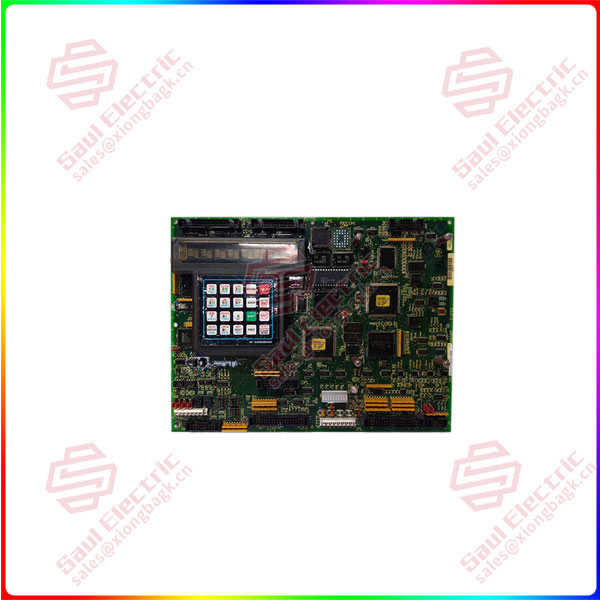

IS200EXHSG3AEC

In the process of serving Shengyi Technology, the global core supplier of electronic circuit substrates, Jingdong Industry relies on the digitalization of performance to help it greatly improve the performance delivery cost. Different from the past slow, small selection of offline local sourcing, Jingdong Industry through the digital supplier collaboration system connected to about 30,000 manufacturers, distributors and agents inventory information, in an intelligent matching way to help Sheng Yi Technology quickly lock-in spot inventory nationwide. At the same time, with the help of the intelligent decision-making system “K2”, Jingdong Industry will also use advanced data analysis and algorithms to evaluate variables such as cost, inventory location, supply quantity and delivery time, and make overall scheduling for brand owners, channel operators and service providers. While making full use of and allocating social resources, it will implement the optimal value performance delivery with the shortest handling distance and the least handling times. To achieve the optimal logistics distribution cost.

On July 12 this year, Jingdong Industry announced that through the original “Mercator standard commodity library”, it took the lead in achieving a unified industrial supply chain “language system”. Jingdong Industry not only serves single-point links such as procurement, but also links and optimizes all links of the supply chain through digital technology to achieve full-link digital services such as goods, procurement, performance and operation.

1 Year Warranty

1 Year Warranty