Landing situation: ABB and other leading manufacturers actively embrace industrial changes

The application of AI in the field of industrial robots is still in the exploration stage, enabling some intelligent recognition and intelligent programming links. ABB, for example, is empowering the e-commerce logistics sector with its AI-powered robotic item picker. According to Statista, global e-commerce revenues are expected to grow by more than 50% in the next five years, from €1.7 trillion in 2019 to €2.6 trillion in 2024. ABB is actively exploring the huge opportunities for artificial intelligence robot solutions in a wide range of applications such as logistics, warehousing, parcel and mail sorting, and according to the company’s website, in February 2020, the company and Silicon Valley artificial intelligence startup Covariant announced a partnership to bring artificial intelligence robot solutions to the market. Covariant’s covariant brain is a general artificial intelligence that allows robots to see, reason, and act in the world around them, completing tasks that are too complex and diverse for traditional programmed robots. Covariant’s software enables robots to do reinforcement learning: adapt themselves to new tasks through trial and error, constantly expanding the range of objects they can pick. ABB and Covariant AI-enabled solutions are deployed for the first time in Active Ants, a leading provider of e-commerce services in the Netherlands.

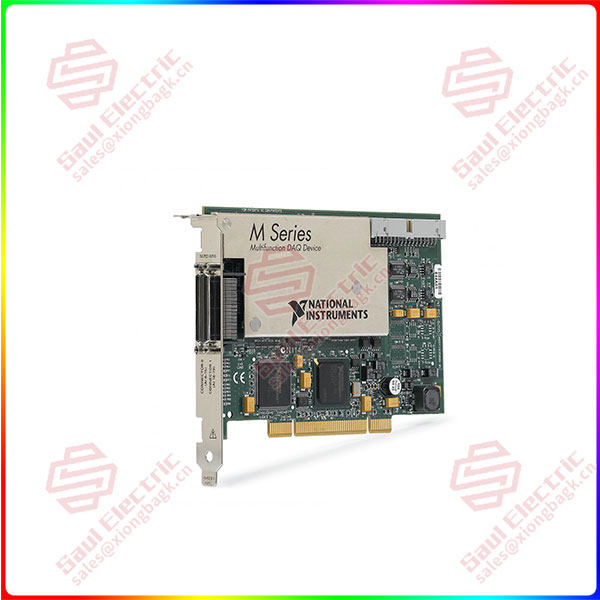

PCI-6255

AI and machine vision enhancement give robots human dexterity, improve the efficiency of picking intelligent recognition and picking speed. According to the company’s website, on April 25, 2023, ABB greatly improved the speed and accuracy of picking by introducing the ability to accurately detect and pick items in unstructured environments in warehouses and fulfillment centers based on artificial intelligence and vision. Using machine vision and artificial intelligence, item pickers can determine the best grab point for each item before the suction fixture picks it up and places it in the designated bin. The system does not require any human supervision or information about the physical properties of the items it picks, is capable of handling a variety of items in a dynamic and unstructured environment, and achieves high-precision picking with an accuracy of more than 99.5% through ABB’s vision system, which can pick up to 1,400 unsorted items per hour. The product is currently suitable for a variety of loads and applications and can be installed into one of three ABB robots – the IRB1200, IRB 1300 and IRB 2600.

ABB partners with Microsoft to use generative AI to empower industrial analytics. According to the company’s official website, on July 5, 2023, ABB partnered with Microsoft to integrate generative AI capabilities into industrial digitalization solutions, with the aim of deploying Copilot functionality, The ABB Ability Genix Industrial Analytics and AI suite and its applications enable more intuitive user interaction, further leveraging the value of linked data to improve efficiency and sustainability. ABB Ability Genix is a comprehensive, modular industrial iot, analytics and AI platform. ABB will integrate generative AI into Genix platforms and applications through Azure OpenAI services, including large language models (LLMS) such as PGT-4, for code, image and text generation. The new Genix Copilot app will enhance the user experience by providing intuitive functionality and streamlining linked data flows across processes and operations. Improve decision quality and increase productivity by providing real-time actionable insights to industry managers, functional specialists and shop floor engineers. According to ABB, such insights have the potential to extend asset life cycles by up to 20% and reduce unplanned downtime by up to 60%.

1 Year Warranty

1 Year Warranty