Myth 7: Lack of correct robot knowledge

Robot manufacturers and system integrators often design a robot unit for just one application, but if the user does not have a stockpile of robot knowledge, they may face failure. The use time of any equipment is closely related to how users use and maintain the equipment. It is not uncommon for some first-time robot users to refuse training. The most important condition for the robot to maintain its normal work is to fully understand the robot’s capabilities and use them optimally within the scope of work.

Industrial robots are very special equipment, and the complexity of their operation is no less than a numerical control machine tool. In the same way, the use of robots needs to be familiar with the basic safety operation of industrial robots, otherwise it is very unsafe for equipment and people. The user of the robot must participate in the safe operation training of the manufacturer’s system before being allowed to operate.

Mistake eight: Ignoring the relevant equipment for robot applications

Teaching devices, communication cables, and special software are often required, but are easily forgotten in the initial order. This will cause the whole production plan to be delayed and over budget. When choosing robot-related equipment, consider your overall needs. It is very common for customers to save money by not integrating some key equipment with the robot, such as the related equipment and software that needs to be configured for the project. During the procurement process, the relevant products ordered should be considered according to the requirements of the project.

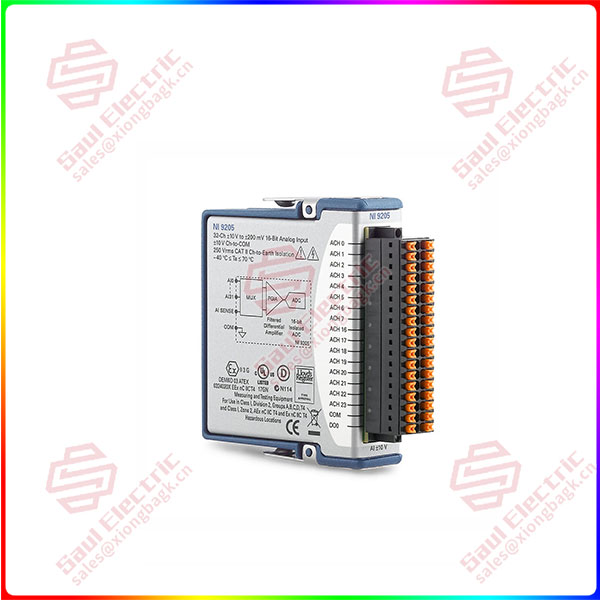

NI-9205 779357-01

Mistake 9: Overestimating or underestimating the robot control system

Overestimation of the robot control system capability will result in system duplication of investment and overbudget costs. It is very common to use double backup on safe circuits. Overestimating the capacity of the control system will generate additional equipment costs, rework and delay costs, etc., trying to control too many I/O ports and increasing the servo system is a common mistake.

Security control is a very important issue, while considering security, we should also try to optimize the application of security logic signal, the repetition of the program is unnecessary.

Myth # 10: The use of robotics is simply not considered

Financial constraints, lack of understanding of robotics and past failed attempts to use robots are the reasons many people stay away from robotics. However, in order to win the final competition in the market, this misunderstanding needs to be corrected, and the use of robot technology can improve efficiency and save time in many cases. Especially for simple operations and repetitive work, robot technology can be used to improve production efficiency. The use of robots in production can ensure the yield of products.

With the emergence of the seventh axis of the robot, it is better to cooperate with the application of the robot, so that the robot uses more space and has more application scenarios, so it is sooner or later that the robot replaces the manual.

1 Year Warranty

1 Year Warranty