Energy Applications White paper released, innovative industrial sensing solutions to safeguard energy security

At the show, TE also released its latest energy applications white paper, Industrial Sensor Applications Development Report (Power and Oil and Gas), detailing the application of its innovative industrial sensors in the two energy pillars of power and oil and gas.

“The energy sector is going strong right now. The expansion of renewable energy industries such as wind energy storage, domestic west-east power transmission, and international transnational natural gas transmission will promote the demand for industrial sensors and technological progress.” Tan Ban Weng pointed out that the production, storage and transmission of energy have extremely high requirements for safety and continuity, and the role of sensors is essential.

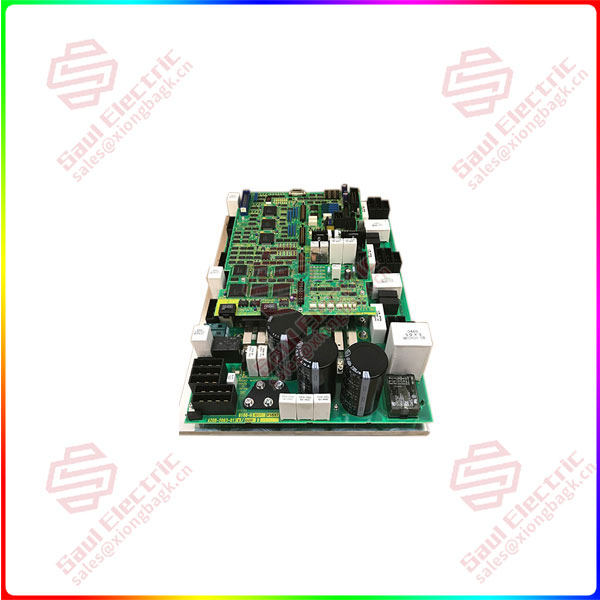

A06B-6100-H001

For example, at the power generation end, the operation status of the power generation equipment is monitored in real time by sensors, so as to judge the health of the entire power generation system, and timely adoption of “predictive maintenance” can effectively ensure the safety and continuity of power production. In view of the needs of power production network, high integration, high sensitivity, TE has optimized the design of its 8911 single-axis wireless vibration sensor product, increased the bandwidth range to 15K Hz, and supported LoRaWAN wireless protocol. Built-in temperature sensor; Reliable packaging ensures long-term accuracy and stability in harsh industrial environments. At the same time, TE also offers 820M1 single axis and 830M1 three axis vibration sensor chips, users can develop their own vibration monitoring module based on these chips, further improve the efficiency of equipment monitoring.

IntraSense is a high-quality product for a wide range of minimally invasive medical applications

The IntraSense micro-invasive pressure sensor, which is small, easy to integrate and has better performance, was also a highlight of the TE booth. The product is a microminiature pressure sensor that is biocompatible and can be installed into small pipes and needles currently on the market, as small as 1FR pipe matching. IntraSense uses resistive MEMS technology and packaged wire/gasket connectors for flexible integration into the tips or sides of catheters and needles; It can also be equipped with optical shielding to increase its photosensitivity by four times and maintain high accuracy even in the body cavity light environment.

IntraSense is designed for minimally invasive medical devices that significantly improve surgical control and achieve better patient outcomes. Since its launch in China, the product has been extensively tested in application scenarios such as blood flow reserve coefficient (FFR), endoscope, and intracranial pressure (ICP), and has received positive responses, especially from users who praise the quality of IntraSense products.

1 Year Warranty

1 Year Warranty