Since the beginning of this year, multiple factors are amplifying the uncertain macro environment, including geopolitics, demographic inflection point and consumption downgrade and other issues, to China’s manufacturing enterprises and automation suppliers at the same time brought challenges – the so-called “internal volume” arrival, so that the industry began to think about how to break the current new situation.

From electrification, automation to digitalization, Weidmuller has been pioneering innovation on this road, and is committed to working with customers to cope with different market situations at different times and stages. During the 2023 Shanghai Industry Expo, the author once again communicated with the directors of Weidmuller’s three product divisions, and comprehensively interpreted how WeidMuller based on product innovation and digital-driven strategy to help customers in traditional industries to successfully transform into emerging industries from electrification, automation and digitalization.

Cabinet electrical design, breaking the digital base

Electrical cabinet design and manufacturing process is a systematic engineering. Through the highly digitized components, engineering design and production documentation of electrical cabinet assembly, Weidmuller provides the game-changer to transform the traditionally cumbersome electrical cabinet design process.

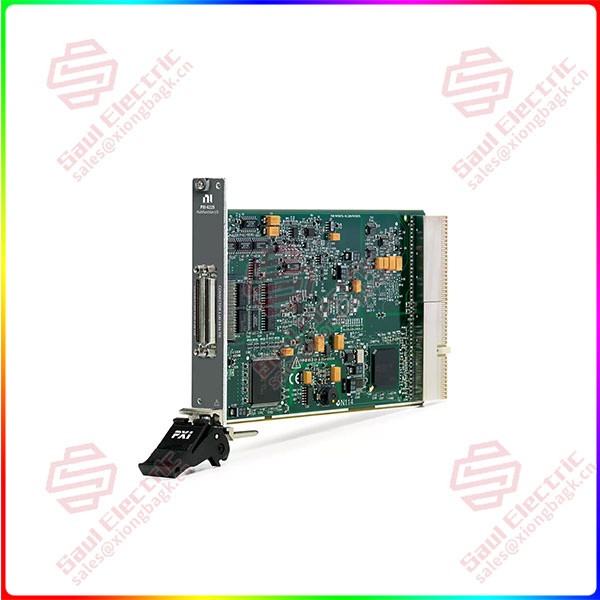

PCI-6225

According to Lars Kosubek, Director of the Electrical Cabinet Products Division of Weidmuller Asia Pacific, Weidmuller is one of the few suppliers that can provide one-stop solutions from the planning, installation and operation of electrical cabinet assembly. These include automatic terminal assembly machines, semi-automatic wire harness machining centers, laser marking systems, automatic wire cutters and wire strippers, and especially the free digital engineering design software WMC, which can provide support for the assembly of cabinets to achieve a complete seamless process, building a data bridge from planning to operation, thereby simplifying and accelerating the assembly and manufacturing of electrical cabinets.

“Cabinet electrical design is a key part of the digital engineering stage,” said Lars Kosubek. “At the Expo, the one-stop cabinet digital solution and the new SNAP IN squirrel cage connection technology, which won the German Innovation Award, attracted many visitors to stop and watch the experience. “According to the introduction, the connection technology combines the advantages of both shrapnel and in-line technology, which is not only fast and simple, the wiring process does not require any tools, but also can be directly inserted to complete the wiring even if the flexible wire of the tubular end is not used, especially suitable for the use of robots to achieve fully automated wiring.” From the initial squirrel-cage device connectors, to squirrel-cage terminals, to squirrel-cage photovoltaic connectors, Weidmuller has integrated them into a wide range of popular products available to customers.

1 Year Warranty

1 Year Warranty