In the long history of human development, the acquisition and processing of food has always been an inescapable topic. Among many essential nutrients for human body, animal protein, as an important nutrient component, is always at the highest level of difficulty to obtain in nature. Dairy, as the best and convenient source of animal protein, has been at the forefront of the Chinese people’s balanced diet pagoda for many years.

In recent years, with the advancement of China’s urbanization, dairy products have the opportunity to enter a broader sinking market. At the same time, China is comprehensively entering the aging society, and the pursuit of health is increasingly affecting the consumption decisions of the people, and dairy products are becoming the consumption choice of more people. According to statistics, in 2023, the scale of China’s dairy market reached about 500 billion yuan, an increase of 10%.

While the market size has reached a new high, China’s dairy market is also facing many challenges: the growth rate of demand has gradually slowed down, and liquid milk consumption has declined for the first time in eight years in 2022; Many domestic and foreign brands are competitive; New consumption situations, such as platforms and social networking, continue to emerge; Consumers’ requirements for dairy safety and nutrition are increasing, and enterprises need to speed up product innovation. Feed prices remain high, bringing unprecedented cost pressures…

In this context, how do major dairy enterprises improve quality and efficiency and tap the potential of market consumption? How to ensure technological advancement, process standardization, transparency and traceability? How to meet the needs of consumers with higher quality, healthier nutrition and richer dairy products? Digital transformation has become the key and industry consensus for dairy companies to “break the game”.

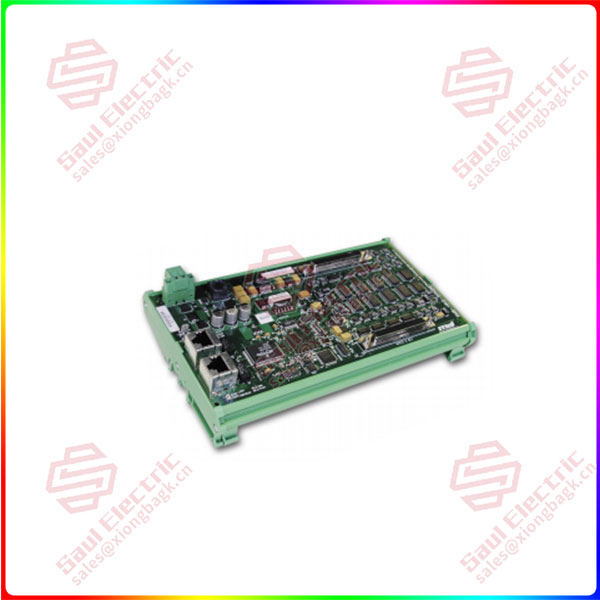

RMB-10V2-SYNQNET

Six factors drive the digital transformation of the dairy industry

At present, the food and beverage industry is promoting digital transformation in multiple forms and initiatives. In the guiding opinions of the Core Index System for the High-quality Development of China’s Dairy Industry, the digitalization penetration rate is required to reach 80% for the management improvement indicators of dairy enterprises; In terms of information reform, the proportion of information investment needs to reach more than 20%, the coverage rate of product traceability system is more than 50%, and the coverage rate of quality traceability system is more than 80%.

However, the dairy industry spans the three major industries, with a wide span, long chain and high integration requirements. Upstream and downstream enterprises have different cognition and usage habits of data, and the digital transformation has long obstacles, which is the process of constantly generating and solving problems. Six factors have become the biggest driving force for the digital transformation of the industry:

Safety compliance: As a consumer product mainly for infants and young children and middle-aged and elderly people, dairy products have been strictly regulated by relevant government departments. Dairy enterprises urgently need to achieve timely, accurate and complete product chain tracking and tracing from raw material formulation to terminal sales, respond to the requirements of regulators, and achieve rapid recall of defective batches, so as to maintain the unified quality that meets consumer requirements and maintain brand credibility.

Digital innovation: The diversified preferences and tastes of consumers have put forward higher requirements for dairy enterprises in various aspects such as product research and development, organizational structure and production management mode. From product design to formula management, from rapid production to packaging innovation, dairy companies must change the production management mode, with the help of digital technology and intelligent manufacturing, in accelerating innovation and research and development efficiency, improve the automation and intelligent level of production equipment, improve flexible production capacity, to achieve rapid production line switching and other aspects of all;

Energy saving and consumption reduction: At a time when feed costs remain high, domestic dairy consumption demand is weak, and raw milk prices are falling, dairy companies need to strengthen science and technology and innovation, and pursue green and more sustainable development. At the same time, the production of dairy industry involves many production processes with high energy consumption. Therefore, improving energy efficiency is an important starting point to enhance the market competitiveness of dairy enterprises;

Agile supply chain construction: As a fast-moving consumer goods, the production and sales volume of dairy products and the number of sales terminals are in frequent changes, and low-temperature milk is more stringent for storage conditions, which puts higher requirements on product logistics efficiency and quality control;

Complete industry chain construction: The dairy industry chain is long, whether it is for the safety and quality of production in each link, or for the possession of high-quality production raw materials, improving the construction of the whole industry chain is the focus of the entire dairy industry. How to scientifically control the construction, operation and maintenance costs of “supporting facilities” is a difficult problem that dairy enterprises must overcome.

To deal with the shortage of labor force: the aging society brings the decrease of labor population year by year, so that enterprises “recruitment difficulties” become “more difficult”, with the passage of time, the cost of employment will increase year by year, too high recruitment and training management costs will become one of the risks that enterprises can not be ignored.

1 Year Warranty

1 Year Warranty