On October 13, 2023, Eaton Electric Circuit Protection and Control Business Division and Heheji (Shanghai) Industrial Control System Co., Ltd. successfully held the logistics industry Solution Summit in Suzhou to explore the new trend of intelligent logistics development with industry customers and partners, and use cutting-edge innovative industrial control products and application practices. Inject new impetus into the intelligent upgrading of logistics warehousing such as airport logistics, factory logistics and e-commerce express delivery.

Yang Yang, General Manager of Low Voltage Business of Eaton Electric Circuit Protection and Control Division in China, looked forward to the development prospects of the global and Chinese logistics automation market, as well as the market opportunities of low voltage components in the intelligent logistics industry. He said that Eaton has complete and advanced logistics automation industry solutions, which will help partners and customers grasp the market growth point of the logistics industry in the next five years, achieve intelligent and convenient, enabling and enhancing efficiency.

Zhang Congrong, product manager of Eaton Circuit Protection and Control Division, introduced that with the deepening of supply-side structural reform, enterprises pay more attention to the intelligent upgrading of logistics to ensure efficient production. Eaton Logistics Automation solutions help equipment manufacturers, integrators, end users and partners to build flexible intelligent logistics systems with high efficiency and low energy consumption, providing new “answers” for the future development of the industry.

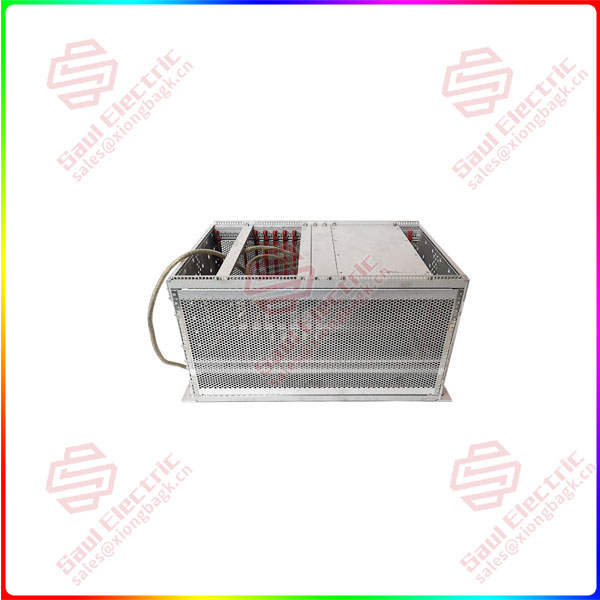

3BSC690076R5

At present, Eaton logistics automation solutions have been successfully delivered to dozens of leading enterprises in airports, factories, e-commerce express delivery and other industries, integrating advanced industrial control technology into complex processes such as baggage transportation, lean manufacturing, warehousing and sorting, enabling efficient operation of enterprise logistics business, and gaining a high degree of market recognition.

Distributed drive innovation architecture

Open the smart future of logistics delivery

Eaton has focused on logistics applications for more than 20 years, and launched a future-oriented distributed drive solution, Rapid Link, which changes the previous large and complex electric control cabinet control model and adopts a distributed layout to help airports optimize the entire life cycle system cost of baggage handling systems (BHS). With full CE, UL, CCC certifications, the product has been installed in more than 250,000 units worldwide and deployed in more than 1,000 kilometers of baggage handling systems.

Simple and efficient: no need for cabinet, unified installation size, standardized connection mode, can rotate the base, suitable for different installation positions.

Flexible configuration: optional maintenance switch, a variety of lock control voltages, built-in brake resistance, STO security function terminals and other functions can meet the needs of customers in different application scenarios.

User friendly: Use Bluetooth accessories and mobile APP to debug and apply products efficiently and easily, bringing better user experience.

Higher energy efficiency: Support permanent magnet synchronous motor, brushless DC motor, synchronous reluctance motor and other high energy efficiency synchronous motor control technology.

1 Year Warranty

1 Year Warranty