With the development of intelligent manufacturing in China, pneumatic actuators slowly can not meet the needs of some high-demand process development. Due to the limitations of the mechanism itself and the working principle, the pneumatic actuator has certain limitations, such as the speed is easily affected by the change of load, the proportion of friction in the thrust is large, resulting in poor stability, the output force is small, the accuracy is low, and the instability of the air source pressure affects the output.

The benefits of electric power are well known. However, there are many obstacles to switching from pneumatic to electric. For most of the long-term use of pneumatic actuator production enterprises on the market, the original production line of many automation equipment has been running very stable, engineers to change to electric very large projects. The cost of “electric ventilation” is too high, not only reflected in the price of the electric actuator is higher than that of the pneumatic actuator, but also in the replacement of the original pneumatic actuator, due to the size, hole location and other differences, customers need to redesign other mechanisms and fixtures, as well as invisible debugging costs and learning costs.

In response to these problems, the RM-EGB compact electric clamp launched by Augmented Intelligence in the first half of this year is very popular, which precisely solves the problem of customer engineers. This is a disruptive and ultra-cost-effective electric actuator product, which can perfectly replace the traditional air claw and provide a more efficient solution for intelligent manufacturing.

Through the highly integrated design of the motor and the drive, and the advantage of the extreme optimization of the algorithm performance, the performance of the motor is directly improved and expanded. Therefore, under the same product volume and size, RM-EGB achieves a higher degree of integration as a whole, and its performance is better than that of similar products. The holding force of RM-EGB is 2-3 times larger than that of similar products, and it can always maintain continuous accuracy and stability of the output, and has a wider range of versatility and practicality.

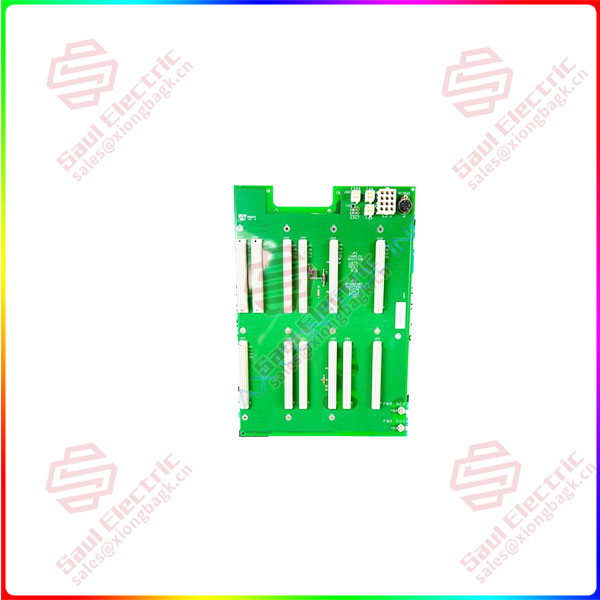

IS200ERBPG1A

The traditional electric gripper needs to use Modbus RTU or other buses to connect to the upper computer, and configure the movement direction by changing the parameters to match or switch the two usage scenarios of the gripper and the external support. The RM-EGB series does not require any configuration, and is fully compatible with both clamping and external bracing application scenarios through simple I/O control, and provides complete clamping/drop detection function status output in both clamping and external bracing scenarios.

Through the I/O combination trigger control, RM-EGB can combine 4 clamping power levels, 2 external support power levels, and 3 absolute positioning positions to meet the customer’s extreme flexible production line requirements without suspending the connection to the upper computer to change parameters. A single input signal can also be used to achieve simple clamping and opening control, directly replacing the original pneumatic control scheme without any program changes.

Engineers can choose the appropriate output gear according to different workpiece types and specifications, which greatly reduces the complexity of debugging. Excellent motion control technology also ensures the accuracy and stability of different forces. Whether it is clamping small screws, small screw caps, or clamping slightly larger workpieces, it can be adaptive clamping without manually adjusting the position. Multiple positioning stroke is optional, more flexible, can easily complete obstacle avoidance, clamping/external support and other complex actions. The RM-EGB is equipped with four mounting holes to directly replace the common cylinder products on the market, such as air compressors, filters, solenoid valves, throttle valves, pneumatic fingers, etc.

The RM-EGB Compact Electric Finger is a disruptive and cost-effective electric actuator that can perfectly replace the traditional air claw and provide a more efficient solution for intelligent manufacturing. The product has been widely used and recognized in many industries and fields, such as battery industry, medical industry, food industry, consumer goods industry, etc. On the road of “electric ventilation”, Augmented Intelligence always adheres to the concept of creating value for customers with technological innovation, and provides customers with more and better products and services.

1 Year Warranty

1 Year Warranty