Recently, Heuxcom extended its netFIELD Industrial iot ecosystem with application container netFIELD App EtherCAT Tap. The application acts as a software gateway to convert process data in the EtherCAT network to the MQTT protocol. By feeding the data into the analytics software, plant operators can benefit from the data with minimal integration efforts, for example, early detection of anomalies in the production process or optimization of the process to increase productivity after analysis.

EtherCAT network configurations can be automatically obtained from TwinCAT or other engineering tools via ENI files and the process data to be published to the MQTT agent is determined in the network tree. Additional information can also be imported by importing ENI project data.

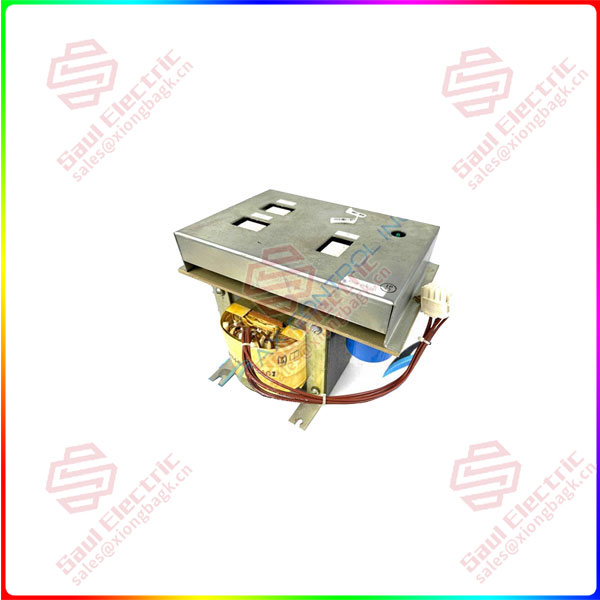

DS2020DACAG1

Key technical information about EtherCAT Tap, the netFIELD application from Heuxun:

Based on Hython’s netX multiprotocol processors (such as those used in computer communication cards or embedded modules), container host systems with integrated industrial network interfaces (such as field deployment level edge gateways) can be used to collect EtherCAT network process data. In addition, the use of netMIRROR, a Heuxen passive Ethernet splitter, enables online monitoring without affecting the EtherCAT network in the event of a container host power outage.

Sample the EtherCAT network continuously or at intervals

Data entry protocol: EtherCAT

Data output protocol: MQTT

MQTT release interval: minimum 1ms

Data can be distributed to any MQTT agent

Data throughput depends on processor performance

1 Year Warranty

1 Year Warranty