Continuous external extension to accelerate industrial transformation

The results are impressive, but Schneider Electric doesn’t stop there. The next step in industrial transformation is to fully harness the power of digital manufacturing systems and apply them not only to individual plants, but also to an organization’s entire production and logistics network and supply chain. These networks may consist of dozens or even hundreds of manufacturing facilities, warehouses, and other factories located in different countries and continents. At Schneider Electric, we have nearly 200 plants, more than 80 distribution centers and thousands of suppliers working together to address Scope 3 carbon emissions.

For many companies, integrating such a complex network is a huge challenge. Many times, individual plants operate independently and use different systems, standards, and methods. However, most enterprises only focus on a single plant or different processes, which makes it difficult to achieve the transformation goal. To better respond to the crisis, organizations need to fundamentally rethink their approach to ensuring that they transform in a systematic, digital, data-driven, and holistic way to drive value and operational performance both within the organization and across multiple plants.

Imagine the huge advances that could be made by the exchange of data between standardized IT systems such as ERP and shop-floor operations technology. Building a connected ecosystem of suppliers and partners with access to orders and inventory across multiple manufacturing facilities will further improve planning, quality and risk prediction. In addition, it will accelerate the goal of achieving net zero and save utility costs by reducing resource consumption and controlling energy rationing. The implementation of all measures requires a clear digital technology roadmap, as well as governance based on data standardization and information security strategies.

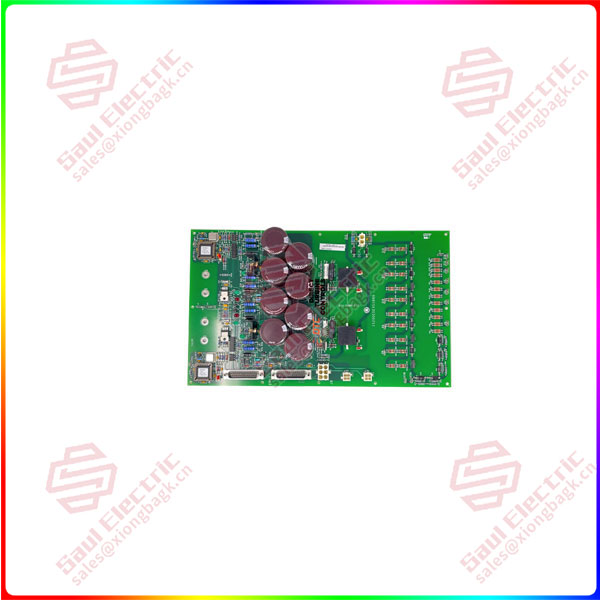

IS200EDEXG1B

Talent is the core of industrial enterprise transformation

Needless to say, all goals require planning, investment and time, and nurturing the right talent is an important prerequisite, which means we strive to attract digital talent with diverse backgrounds, and continuously provide opportunities for employees to enhance their professional skills. At the same time, we also need to shift our mindset, only when companies, teams and individuals recognize the strategic importance of integrated organizational operations, not limited to short-term goals, can we maximize the long-term potential of technological change for the industries of the future.

In order to meet the challenges in the coming years and decades, the industrial sector needs to leverage the complementary advantages of humans and machines to further promote transformation and upgrading, which also means the need to improve efficiency through data-driven enterprise-wide, and continue to increase employee investment, carry out corresponding skills upgrading and training. To help industries move towards an open, efficient, resilient, people-centred and sustainable future.

1 Year Warranty

1 Year Warranty