Throughout the history of mankind, every step of the leap, can not be separated from the figure of the machine. The steam engine promoted the first industrial revolution, the internal combustion engine ignited the second industrial revolution, and now the reform with a new generation of information technology as the core has not dissipated, and the Industry 4.0 era has arrived.

For the machine, people always have a complex emotion that can not be explained, the root of which is that human “fear” of robots or is starting from the roar of steam engines. Science and technology change life is not a slogan, but a living reality, but under the tide, the technology threat theory is rising. On the one hand, people hope that science and technology will advance, but on the other hand, they are wary of it going too far, and they are afraid that it will be replaced by machines.

However, with the deepening of industrialization, the continuous improvement of productivity, the change of population structure and labor costs, labor shortage has become an unavoidable new issue of The Times. Today, with the demographic dividend fading and the aging accelerating, the nature of the manufacturing industry’s repetitive and labor-intensive assembly line determines that it is difficult to become a “good match” for the young generation to “rectify the workplace”, and for relevant enterprises, raising wages and recruiting workers can only solve the urgent need.

In this context, industrial robots that do not touch fish, do not complain, and work without interruption 24 hours are gradually replacing artificial production pillars.

This is especially true for China, the “infrastructure monster”.

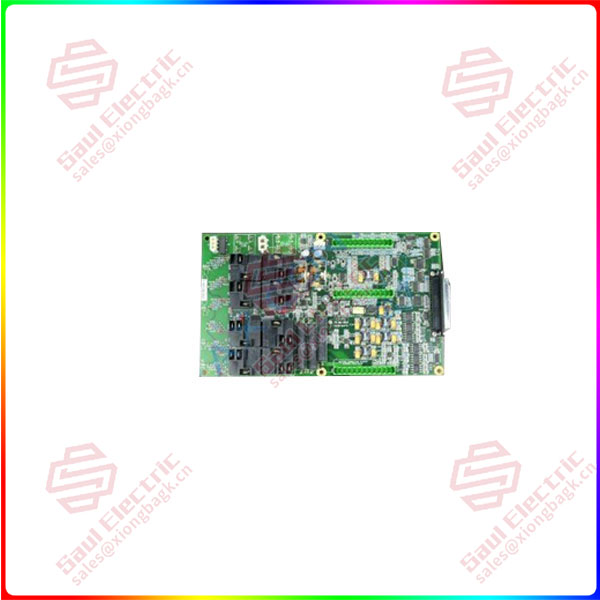

IS200AEAAH1A

According to the latest “2023 World Robot Report” released by the International Robotics (IFR), 553,052 industrial robots are newly installed in the world in 2022, and China, as the largest market, will reach 290,258 installed units in 2022, once again breaking its own record and occupying half of the global market.

As the “pearl at the top of the crown of manufacturing industry”, industrial robots’ research and development, production, manufacturing and application are an important sign to measure a country’s scientific and technological innovation and high-end equipment manufacturing level.

But today’s industrial robot market, half is fireworks, half is the tide, Matthew effect is obvious, the “four families” all year long sit on the dominant position, occupying more than 70% of the market share of China’s robot industry, almost monopolizing automotive manufacturing, welding and other high-level fields.

Recently, the “four big families” are more frequent actions, and the industrial robot industry war continues to heat up.

01

Who are the “Four families”?

In 1959, the United States Unimation company launched the world’s first industrial robot.

The wind of industrial robots started in the United States, but did not stay here for long, but blew across the ocean.

In 1967, Japan introduced the first industrial robot from the United States, and in the next two decades, Japanese industrial robots showed an explosive growth trend, and gave birth to Fanuc and Yaskawa electric two giants.

In Europe, Germany Kuka developed the world’s first electromechanical drive six-axis robot in 1973. In 1974, ABB of Switzerland launched the world’s first fully electronically controlled industrial robot.

At this point, the “four families” gathered.

1 Year Warranty

1 Year Warranty