Industry talent shortage

Machine tool industry talents need to have software knowledge and understand the hardware structure, high requirements for personnel, at present, through the cooperation with Northwestern Polytechnical University, Beijing University of Aeronautics and Astronautics, Huazhong University of Science and Technology and other universities, training a large number of engineers, but the machine tool industry salary level compared with the Internet and other industries, and the office location is mostly three or four tier cities. The environment is relatively poor and less attractive to engineers. The lack of industry talents will affect the introduction of advanced technology and the use of high-end equipment, and seriously affect the industry’s R & D innovation and development capabilities. The company needs to extensively establish and improve the training, salary, performance and incentive mechanism, enhance the attractiveness of talents, and vigorously introduce technical talents with technical innovation ability, management talents with management work experience, market development talents with project marketing experience and other outstanding talents.

The retained profits of domestic enterprises are low

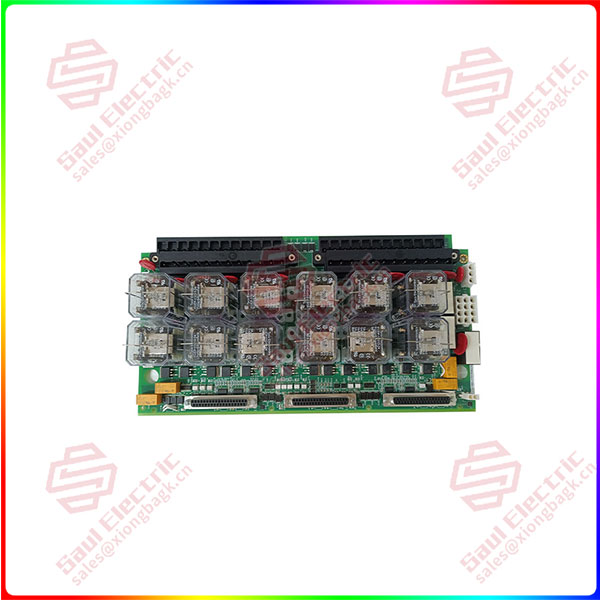

IS200TREGH1BEC

The iterative upgrading of technology and products of industrial machine enterprises requires a large amount of R&D investment, and the market acceptance of new products also requires a certain period. Therefore, the industrialization and marketization of research and development results are affected by market demand, customer recognition and other factors, and there is uncertainty. At the same time, for most of the domestic industrial machine enterprises, the net profit can reach 10% is not easy, there is no surplus retained earnings to support large-scale research and development investment and after-sales service, which will affect the sustainability of the company’s development, private enterprises can only undertake major national research and development projects through the way of bonding.

Domestic CNC machine tool industry concentration and market share is low

The total market share of the top ten listed companies before 2022 is only 8.8%. Among them, the largest domestic machine tool revenue of Genesis 2022 CNC machine tool business revenue of 4.422 billion yuan, the market share of only 2.40%, according to the 2022 metal cutting machine tool consumption of 124.03 billion yuan estimates, its market share is only 3.57%. Due to the generally small scale of enterprises, a single enterprise can not invest a large amount of capital for R & D innovation, nor can it undertake major scientific research projects in the national industrial field, resulting in a widening gap between domestic machine tools and foreign leaders in the high-end field, and insufficient brand competitiveness.

China is firmly seated in the leading position of the world’s manufacturing countries, which has laid a deep foundation for the rapid development of industrial machines, and put forward higher requirements for the high-quality development of industrial machines. At present, the long-term trade deficit of China’s machine tool industry as a whole is gradually shrinking, marking that domestic machine tools are moving step by step toward autonomous, controllable and localized development. The value of export machine tool products continues to increase, and domestic machine tools are constantly moving toward intelligence and high-end.

1 Year Warranty

1 Year Warranty