If personnel must often enter dangerous areas or feed manually, it is suitable to use optical sensors with protective devices for safety protection. Pilz’s security radar system PSENradar, security laser scanner PSENscan and light screen PSENopt II provide “tailor-made” support to the user.

According to the general rule of thumb: as long as the photosensitive conditions are good, and the environment is relatively clean, the scanner or grating is a good choice. The radar sensor is not only suitable for rough environments with pollution and dust, it is also an ideal protection measure for extreme temperature differences and bad weather conditions. If the goal is to detect objects in three-dimensional space, such as to prevent danger from behind, radar technology should also be considered. Gratings and scanners can protect two-dimensional surfaces such as passageways and floor areas.

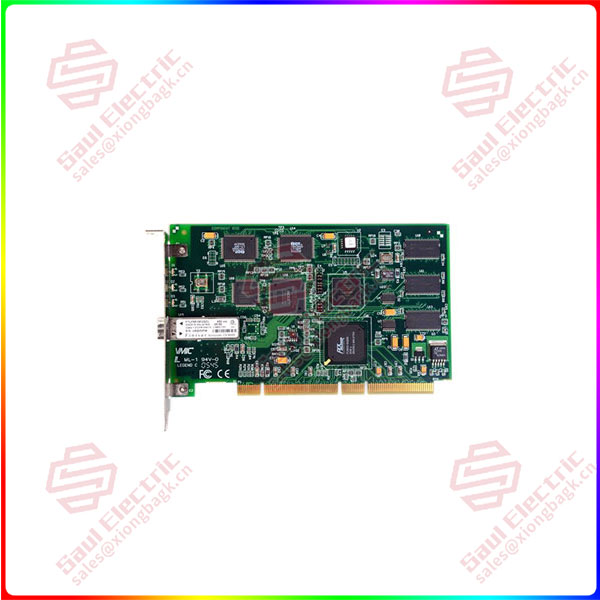

VMIPCI-5565

Rasters detect static obstacles, while scanners provide protection and dynamic navigation for mobile applications, such as AGV systems. The latter protection also covers static application scope, access control or even protection from hazards that come from behind. As mentioned earlier, radar sensors can also do this. Again, for each case, there are several criteria that determine which type of protection technology can and should be used.

The safety grating is mainly used in situations where an accessible safety solution must be implemented because the process is not 100% fully automated and the operator must intervene in the process through an open access point. If an intervention point or an application’s access point needs to be monitored securely, with high resolution and short response times, then they are the right choice. But when the whole area is protected with different protected areas, the scanner technology is appropriate because it can also provide precision in terms of edge clarity. Normally, scanners can detect every type of object. Radar sensors can detect objects with specific materials, such as water and metal. When and which type of sensor to use depends on the application. But no matter what the production task: the right protective measures can reduce production risk and increase productivity.

1 Year Warranty

1 Year Warranty