On December 26, the “Made in China Day” kicked off again. This year marks the eighth edition since the first one in 2016. Manufacturing in China is the foundation of the country, the tool of rejuvenation, and the basis of strengthening the country. Manufacturing is the main body of the real economy and the lifeline of the national economy. The report of the 20th Congress proposed to increase support for advanced manufacturing, and the Central Economic Work Conference in December this year emphasized that scientific and technological innovation leads the construction of a modern industrial system.

A look at the climb of Made in China from the “Made in China Day”

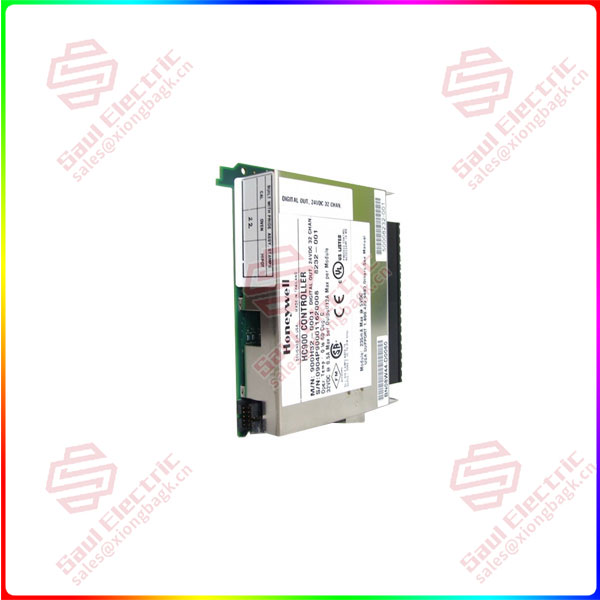

900CP1-0200 As a landmark event in China’s efforts to promote the high-quality development of manufacturing and build the “Made in China” brand, the 8 years of the growth of “Made in China” is also the 8 years of rapid growth of Chinese manufacturing. In these 8 years, we have witnessed the transformation of Chinese manufacturing, from low-end to high-end, from foundry to brand, from labor-intensive industry to technology-intensive industry evolution.

China’s manufacturing enterprises, for a long time in the global division of labor system, bear almost the most basic processing and manufacturing links, “cheap” or “cheap goods are not beautiful”, has become many people’s stereotype of “made in China”. If it does not have core technology and brand assets, China’s manufacturing industry can only participate in international competition through “price advantage”, but this allows factories to fall into a vicious circle of low profits or even negative profits, usually not only difficult to 900CP1-0200 afford research and development costs, even basic worker treatment can not be guaranteed. The way to break the game is actually very simple: go up.

To go up is to make the entire industry achieve real industrial upgrading and climb the upstream of the industrial chain. According to the smile curve theory, the upstream of the industrial chain is often a relatively profitable, competitive industries and companies, they often have high barriers to entry, such as technology, brands or resources, so for latecomers, to achieve such a “counterattack”, it is not easy.

But many Chinese companies have succeeded.

The first is the car industry. For industrial countries, the automobile industry is the real “industrial pearl” – because this industry concentrates the characteristics of high profits, high value, and high technical barriers, and the related supporting industry chain is very large, a successful automobile manufacturing enterprise, often can become a city, a region and even a country’s economic growth “engine”. It has led to the vigorous development of a series of supporting industries, and has spawned more new jobs and new technologies. The industrial powerhouses of the United States, Europe, and Japan all have strong auto industries on their way to development. It can be said that the automobile industry is not only a pillar industry, but also a core industry for the upgrading and development of a country’s manufacturing industry.

900CP1-0200

The development of China’s auto industry is there for all to see. China’s automobile industry started in the 1950s, after imitation, introduction and then to the independent brand strength, these years in the field of new energy vehicles blooming, but also let the Chinese automobile industry to achieve the “corner overtaking”.

China’s auto market is undergoing an iterative upgrade, and the rise of China’s own brands is rapidly encroaching on the market that originally belonged to foreign auto brands. According to the statistics of the Passenger Federation, the Chinese auto market is expected 900CP1-0200 to reach 29.5 million units in 2023, another record high. Moreover, the market share of independent brands has been greatly improved. In October 2023, the retail sales of independent brands were 1.13 million, an increase of 20% year-on-year and 5% month-on-month. The domestic retail share of independent brands in the month was 55.6%, an increase of 4 percentage points year-on-year. In 2023, the cumulative share of independent brands is 51%, an increase of 4.9 percentage points. At the same time, mainstream joint venture brands retailed 680,000 units, down 2% year-on-year and up 1% quarter-on-quarter. Among them, the retail share of German brands was 18.1%, down 1.2 percentage points year-on-year; The retail share of Japanese brands was 17.7%, down 1.2 percentage points year-on-year; The retail share of the American brand market reached 6.1%, down 0.8 percentage points year-on-year.

Not only in the internal market, Chinese cars are also rapidly expanding into the global market. According to the China Automobile Association data, in the first half of 2023, China’s automobile exports were 2.341 million, an increase of 76.9%. From January to November, China maintained a high export growth rate of automobiles, with cumulative exports reaching 4.412 million units, an increase of 58.4% year-on-year. It is expected to break through the 5 million export mark in 2023 and remain the world’s number one. Byd, Chery, NIO 900CP1-0200 and other self-branded cars have entered overseas markets and quickly become highly competitive local models – and their competitiveness comes not only from price, but also from design and technology. For example, BYD’s original “blade battery” can not burst into flames when it is impacted and pierced through acupuncture experiments, bringing more safety to electric vehicles.

The booming development of the automobile industry has also led to hundreds of other industries, one of which is the CNC machine tool industry. CNC machine tool is one of the foundations of the contemporary manufacturing industry, all kinds of metal cutting and forming can not be separated from it, and the industry on the mold accuracy of higher and higher requirements, but also put forward higher requirements for the technology of CNC machine tools. In recent years, driven by the relevant upstream and downstream industries and the inclined support of national policies, the domestic CNC machine tool industry has been greatly developed, domestic CNC machine tool enterprises have made great progress in technology research and development, and the performance of some high-end products has reached the international advanced level. At the same time, the wide application of domestic CNC system also provides a strong guarantee for the development of CNC machine tools. In the market demand, with the rapid development of automotive, aviation, aerospace and other industries, the market demand for CNC machine tools continues to grow. At the same time, the upgrading and transformation of the domestic manufacturing industry also requires a large number of high-precision and efficient CNC machine tools as support. Not only that, the position of China’s CNC machine tool industry in the international market is gradually improving. According to the data released by the China Machine Tool Industry Association, in 2020, the import and export trade surplus of China’s machine tool industry reached 9.36 billion US dollars, an increase of 35.9%, of which the total export reached 11.72 billion US dollars, an increase of 29.5%. This shows that China’s CNC machine tool products have a high competitiveness in the international market.

Whether it is the automobile industry, or CNC machine tool industry, can be called the modern industrial manufacturing industry in the typical high value-added, high-tech high-end industry, Chinese products, Chinese enterprises and Chinese brands in these industries, proving that the “upward” of China’s manufacturing industry is not only a vision, but also a reality.

1 Year Warranty

1 Year Warranty