The challenge of parallel supply chains

Although China has vigorously defended itself against U.S. influence through supply chain control, Chinese manufacturing is not competing with U.S. manufacturing efficiency. It is unlikely that the United States will establish a complete supply chain system in its home country, and its manufacturing reflux looks lively, but it is still clustered at the top of the industry, and cannot benefit the grassroots. It’s a structural crack. The various measures promoted by the United States, whether it is near shore manufacturing or near shore manufacturing, are establishing new connections and eroding the advantages of China’s supply chain.

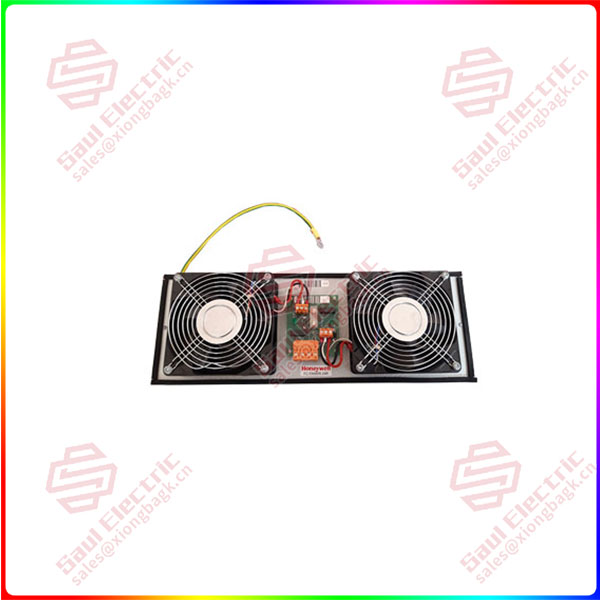

FC-FANWR-24R Therefore, the defense object of China’s supply chain is not the United States’ onshore manufacturing, but the second set of supply chains composed of Southeast Asia, South Asia, Mexico and so on. The real competition for Chinese manufacturing comes from parallel supply chains.

A robotic arm is at work in the “future factory” of an intelligent manufacturing benchmarking enterprise in Hangzhou, Zhejiang province, May 22, 2023. Photo by Du Xiaoyi/Xinhua News Agency

FC-FANWR-24R Different production plants are springing up around the world, trying to build new and efficient supply chains to counter China’s established advantage. The plants that have sprung up have a lingering loophole: some were built to spread risk in “backup capacity”, making it difficult to achieve rapid efficiency gains; Some factories, even at full capacity, require the rest of the supply chain to match the same speed. These factories generally have the problem of insufficient connection, and the resulting supply chain substitution will always be in a supporting position because of inefficiency.

The core of the second set of supply chain growth is to form an efficient relay, but the growth of the relay takes a long time. Even if a lot of control is loaded on it, there is still a lot of uncertainty about the growth of the relay. The organization of the labor force and the network effect of the supply chain will have a greater impact on this.

In Mexico, the backlash from rapid factory expansion is already being felt. Rising labor costs are eroding the advantages of nearshore manufacturing in supply chains.

FC-FANWR-24R

FC-FANWR-24R Mexico enjoys the benefits of an integrated trade agreement with the United States and Canada, but is also subject to tariff-free conditions. The United States-Mexico-Canada Agreement (USMCA) requires that a certain percentage of components be sourced from factories where workers earn more than $16 an hour. U.S. and Canadian factories are easy to reach, but workers in Mexican factories are mostly paid well below $10 an hour. Mexican companies can either increase the proportion of their purchases in U.S. processing plants to enjoy zero tariffs, or take advantage of the lower costs of Mexican plants but continue to pay tariffs.

Foxconn’s Mexico plant is working to improve productivity, and an important move is to replace the basic labor force. Many workers on its production lines are illiterate and unable to read the operating procedures, which seriously affects quality and efficiency. When China’s manufacturing industry was just starting, Foxconn’s educational requirements for workers were higher than high school. Later, a large number of manufacturing experts and technical experts emerged among these skilled workers, enriching the entire labor force. Whether Foxconn’s replacement plan can be implemented smoothly is a test of Mexico’s educational foundation and human resources, and the outcome remains to be seen.

Mexico’s shortage of employable population size and engineers is growing rapidly and will take longer to ease. The upgrading and upward breakthrough of China’s supply chain also takes time, which is a process of scrambling for time and efficiency.

China’s supply chain needs to complete the overall layout under this time window, participate in the construction of parallel supply chains, and participate in the establishment of a new balanced order, otherwise it will be thrown out of the global division of labor system, and the first set of supply chains will lose vitality.

FC-FANWR-24R Consolidating bases at home is as important as building positions abroad.

In the supply chain war, there are three elements that determine the duration of the cycle. The first is the high efficiency and resilience of the global link formed by the domestic supply chain, the second is the weakening momentum of the dominant control of developed countries, and the third is the growth rate of the manufacturing base in less developed countries. Behind these three elements, there is the shadow of supply chain design.

China is entering the deep water zone of industry. On the one hand, it is to tackle the key problems of industrialization and break through the obstacles of technological fault. On the other hand is the fine industrialization, to solve the imbalance of capacity gap. The former has received sufficient attention, and the latter has not been adequately addressed. Fine industrialization needs to face the gap in industrial thinking, which is still the focus of quality issues. The Japanese and German industries have been deeply baptized by the quality culture, and the quality concept shows a balanced distribution in the entire supply chain. However, China still needs to make greater efforts to further strengthen the advantages of Lianrelai with the guidance of “quality thinking”.

1 Year Warranty

1 Year Warranty