Thirty years ago, mechatronics began to take root in China’s manufacturing industry, and 30 years later, intelligent manufacturing and intelligence have become a new driving force for the development of manufacturing. On December 14, the 30th anniversary celebration conference of the China Mechatronics Technology Application Association was held in Beijing. Professor Qu Xianming, member of the National Manufacturing Power Construction Strategy Advisory IS200TTURH1CFD Committee and director of the Manufacturing Research Office of the Chinese Academy of Engineering, reviewed and looked forward to the development process from mechatronics to intelligent manufacturing. The melting of technology and the integration of industries is an important way of technological and industrial progress, and calls for great attention to the intelligent transformation of livelihood industries.

In the 1970s, the concept of mechatronics was introduced into China, and in the 1990s, China proposed that “informatization drives industrialization, industrialization promotes informatization”, and began to promote the application of CAD, CMA, MRP2 (ERP), which can be said to have begun the stage of digital manufacturing. In this century, the Internet has been widely used in China, and digital manufacturing + Internet is also known as digital networked manufacturing. In recent years, with the breakthrough of artificial intelligence technology, digital networked manufacturing plus artificial intelligence, the real intelligent manufacturing has arrived.

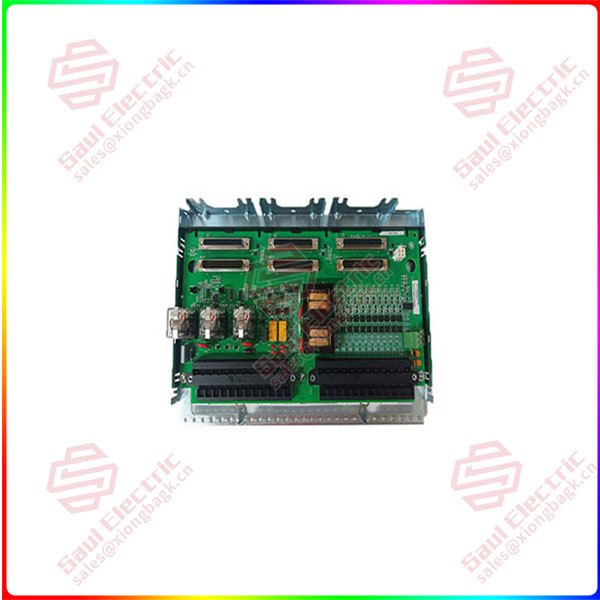

IS200TTURH1CFD Mechanical and electrical integration, intelligent efficiency of the manufacturing industry is very significant, a very traditional product, through mechanical and electrical integration, intelligent transformation will become a high-tech product. The traditional manufacturing industry will become an advanced manufacturing industry after the transformation of mechatronics and intelligence. Mechanical technology and computer technology, microelectronics technology, information technology closely combined, from hardware to software, the function and performance of mechanical products and manufacturing process to a new level, so that the composition of mechanical products have changed, the economic effect and social benefits are huge. The typical product of this revolution is the numerical control machine tool.

IS200TTURH1CFD “From the evolution process of the four industrial revolutions, the history of the industrial revolution is actually the product of technological integration and industrial integration. The third Industrial Revolution (the digital age) can also be said to be the fruit of mechatronics.” Qu Xianming said.

At present, closely related to people’s lives of textile, clothing, food, beverage, furniture, home appliances, toys and other industries, as well as steel, petrochemical, building materials and other industries, many experts call it the traditional industry, but also the livelihood of the industry, some people think that this is the sunset industry, can not see the future, but in fact it is not. Qu Xianming believes that traditional industries are relative to emerging industries, generally labor-intensive industries, mainly manufacturing and processing, they are more urgent to use new technologies, new production tools and production methods to replace traditional technology and production tools.

IS200TTURH1CFD

“The new generation of information technology represented by the Internet will change the way of life of humans, and will also bring revolutionary changes to traditional industries, traditional manufacturing + Internet will move toward digitalization, networking, coupled with artificial intelligence, and eventually intelligent manufacturing.” Traditional industries will become advanced manufacturing after transformation and upgrading, and sunset industries will also become sunrise industries.” Qu Xianming said.

IS200TTURH1CFD Quanzhou in Fujian Province is a traditional industry focusing on textile, clothing, shoes, building materials, furniture, food and beverage. From 2015 to 2018, the industry in Quanzhou has undergone great changes: First, promoting automation, digitalization, networking, and intelligent transformation has become a common demand, and more than 2,200 enterprises have participated. Second, personalized customized production has been recognized by more and more enterprises, and it is promoted in the body. Third, e-commerce has shifted from resistance and fear to acceptance and embrace.

Data show that after four years of development, Quanzhou completed regional production of 846.798 billion yuan in 2018, an increase of 8.9%, and the total volume and growth rate continue to maintain the leading position in Fujian Province. In the first nine months of this year, Quanzhou’s exports bucked the trend and increased by 17.9%. Quanzhou’s experience shows that the traditional manufacturing industry is not a sunset industry, as long as the transformation IS200TTURH1CFD and upgrading, it can become a sunrise industry and a sun industry.

In fact, the Chinese Academy of Engineering recently compared China’s manufacturing industry with foreign countries, one of the unexpected and reasonable results, which is including the textile and garment industry, home appliances industry, steel industry, petrochemical industry, building materials industry, food industry, including the six traditional industries, is the most advantageous and competitive sector of China’s manufacturing industry.

Qu Xianming hopes that the China Mechatronics Technology Application Association can continue to play a role, and can keep up with the pace of The Times, and become an active promoter of the third and fourth industrial revolution.

1 Year Warranty

1 Year Warranty