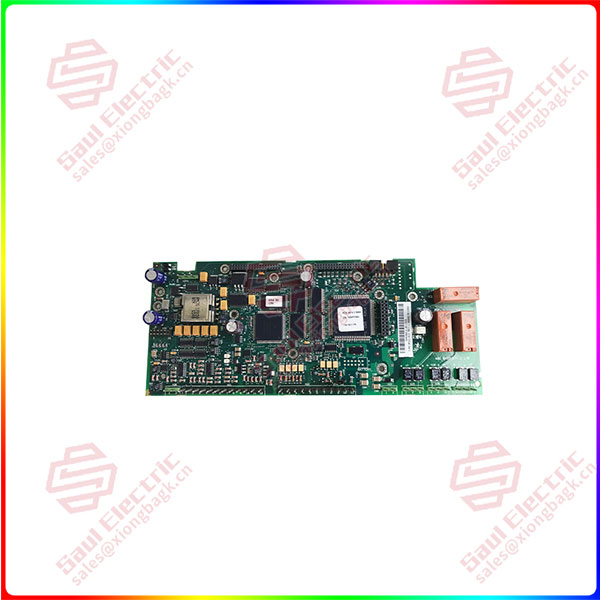

Machine vision changes the future of industry

RMIO-01C As industrial automation increases and the number of smart devices grows, the data created by iot devices will grow exponentially. In a variety of industrial applications, machine learning (ML) can use this data intelligently, and machine vision (MV) systems can obtain valuable data, after sorting useful data, identifying patterns, these data can be used to analyze and improve industrial operations, avoid mistakes in decision-making, and improve processes such as predictive maintenance and user experience.

Machine vision replaces the human eye, allowing robots and computers to visually perceive and interpret their surroundings. They use advanced imaging technologies such as cameras, sensors, and imaging processing algorithms to simulate the ability of human vision and enable it to be used to enhance business processes. This means that machines can perform tasks that require visual inspection or analysis, extract meaningful information from an image or video stream, and use that information to make intelligent decisions.

RMIO-01C Currently, machine vision is one of the most exciting Industrial Internet of Things (IIoT) and Industry 4.0 technologies, and its emergence will revolutionize the operation of industrial supply chains. According to MarketsandMarkets Research, the global machine vision market was valued at $11.1 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 7.4% over the 2022-2027 period to reach $17.2 billion by 2027.

The market driver for this growth is mainly due to the increasing demand for enhanced quality control and inspection. Integration with collaborative robots and artificial intelligence (AI) will dramatically increase the level of industrial automation in warehouses, manufacturing plants and throughout the supply chain. When machine vision is integrated with IIoT (Industrial Internet of Things) devices, the system achieves greater independence and advanced decision-making capabilities. By using algorithms to improve the intelligence of machine vision, manufacturers can gain a better understanding of system operations, plants and factory activities, and implement advanced inspection processes.

RMIO-01C

Integrating IIoT applications with machine vision will bring many benefits, such as:

RMIO-01C 01 Reduce network bandwidth

Machine vision has a wide range of applications in inspection. High-performance camera systems enhanced by AI sensors allow immediate analysis of data at the data source, dramatically reducing the need to transfer data to cloud servers and saving network bandwidth.

02 Improve manufacturing efficiency

In manufacturing, AI machine vision is often used in robot guidance systems where machines can communicate directly with each other rather than through a central enterprise server. The data load on the network is reduced, and the efficiency of data processing is improved.

RMIO-01C 03 Predictive Maintenance

Another notable feature of machine vision is the ability to emit warning signals. When maintenance and repair is required, advanced IoT systems can predict failures and the required repair measures, avoiding total downtime due to equipment failure.

04 Enhanced customer experience

Machine vision is significantly changing the way businesses serve by adding more automation, enhancing data analysis, and communicating what they need to know. Through the use of machine vision, businesses can create creative, personalized and unique user experiences and recommend the right products to influence customer buying behavior.

1 Year Warranty

1 Year Warranty