“A traditional enterprise that produces small kitchen appliances, through digital transformation, has established a central monitoring system for the supply chain, concentrating nearly two thousand suppliers, parts DS200DCFBG1BKC manufacturers and distributors in a monitoring system, not only controlling the quality of parts and raw materials before the supplier leaves the factory, but also greatly shortening the time from obtaining orders to factory shipments.” Recently, in the “‘ Digital enterprise resilience Growth ‘Industrial Internet Cloud Salon” jointly organized by the Industrial Internet Lab, the Economic Observer and Kingdee, Yang Ya, a full-time external director of the central enterprise, shared with the guests the transformation case of an enterprise. He said that in a complex environment, by transforming to digital, some enterprises not only play the advantages of supply chain integration, but also consolidate industrial processing capacity and maintain sustained and rapid growth.

This year’s government work report DS200DCFBG1BKC proposed to “promote industrial digital transformation” and “improve the governance of the digital economy.” As more and more enterprises realize the challenges and opportunities of digital transformation, and have promoted the digital process from the mode, management, organization, technology and other aspects, most enterprises in China have ushered in a new wave of digital transformation.

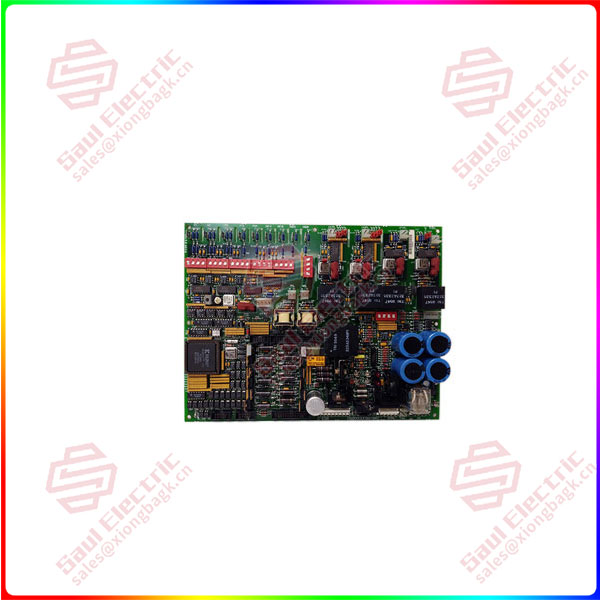

DS200DCFBG1BKC

Data-driven: take digitalization as a tool to enhance the core competitiveness of enterprises

“In the digital wave, the core competitiveness of enterprises is actually the use of data.” Said Li Xiaodong, a researcher at the Chinese Academy of Sciences and director of the Internet Governance Research Center DS200DCFBG1BKC at Tsinghua University. In the past few years, many enterprises have done a good job in business informatization, but it is not enough from the penetration rate, because the cost is too high, especially in the production process of traditional manufacturing enterprises, the dependence on people is very large. If the reliance on people is too strong, once people’s actions are limited because of force majeure factors, the production of enterprises will be affected. Li Xiaodong suggested that in both management and business lines, enterprises should shift from dependence on people to dependence on data.

Chen Yan, vice president of Dazu Laser Group, agreed with Li Xiaodong’s view. He took Dazu Laser Group as an example, in the early days of the epidemic, engineers could not go out, and the products of each decentralized manufacturing base could not come in, “some core devices and core products, our engineers simply had no way to confirm in the first time.” Later, the group accelerated the digitization process in core products and user services, and conducted digital thinking training for employees from the management level to the grassroots, “Especially the core devices and core products, it is clear that these products will not have some problems in the future, we made plans in advance, and remote training for customers.” In 2021, the sales revenue of Dazu laser reached 16.3 billion, “among which the company’s digitalization is very important.”

1 Year Warranty

1 Year Warranty