Logistics industry solutions

Intelligent logistics conveying and sorting system is the core subsystem of material handling and warehousing, and is the key equipment to perform the functions of commodity entry/exit, dismantling and picking, review and packaging, and path sorting, like the aorta runs through the whole process of logistics.

With the rapid development of e-commerce, the operation efficiency, accuracy, stability, online rate and processing capacity of conveying and sorting systems and equipment are important factors that determine the operation efficiency, operation cost, operation quality and user satisfaction of warehouse distribution centers and modern logistics systems. Intellectualization, modularization and standardization have become the key factors and development trends affecting the performance of conveying and sorting systems and equipment.

DYTP600A The LS series discrete IO module launched by Deckwell in this exhibition is a distributed product developed based on the self-developed bus WELLBUS. The series module uses signal superimposed on the power supply to transmit signal and power supply at the same time, and can freely choose the topology structure. In addition, the compact module structure provides customers with more design space. Can be used in logistics warehousing and other points scattered, flexible layout occasions.

Solutions for the automotive industry

In recent years, China’s automobile industry has developed rapidly, joint ventures and self-owned brand enterprises have built factories all over China, in order to improve profit margins and brand market share, advanced field equipment and technology have become more important, and automotive automation technology has also been rapid development. The automobile manufacturing industry has a large scale and high automation requirements, and the automation products involved include fieldbus, control products, motion control, sensors, safety products and so on.

In the four major processes of the automotive production line (stamping, welding, final assembly, painting), each process will use a large number of remote I/O control and acquisition.

The automotive industry production site environment is harsh and installed with a large number of sensors and actuators, the SD series IO module launched by Deckwell this exhibition, with a protection level of IP67, and the use of fully sealed miniization design, compact structure easy to integrate and install, suitable for long-term stable operation and in a variety of harsh industrial environment application scenarios. And the product also has a strong anti-interference ability, so that flexible installation in the field, efficient communication, so that customers can better benefit from intelligent data acquisition and communication solutions.

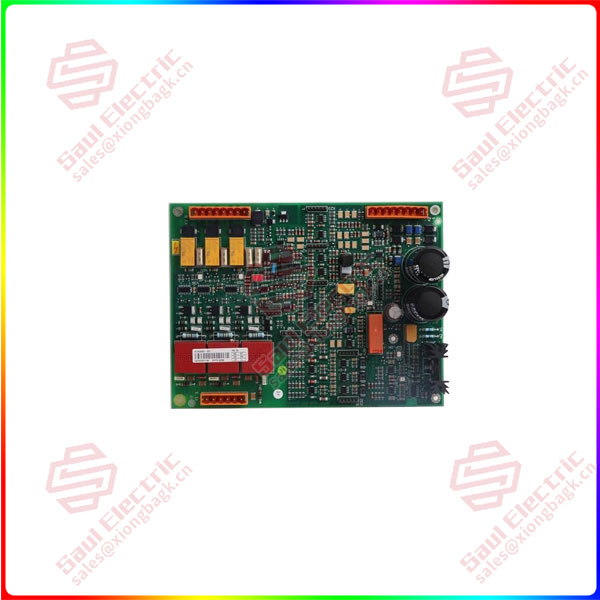

DYTP600A

Semiconductor industry solutions

Equipment in the semiconductor industry is generally divided into front-track equipment and back-track equipment. The front path refers to the processing process of the wafer manufacturing plant, which completes the processing of the circuit in the blank silicon wafer, and the factory product is still a complete round silicon wafer. The back channel refers to the process of packaging and testing, the round silicon wafer is cut into a single chip particle in the sealed test plant, the package of the shell is completed, and the terminal test is finally completed, and the factory is a semiconductor product. The control system of semiconductor equipment requires fast information transmission speed and high precision, so the network requirements are also relatively high.

In response to the strong demand of semiconductor industry customers for equipment miniaturization, the PT series plug-in board I/O modules introduced by Deckwell can be customized to integrate the relays, loads, prefabricated plugs/terminals (such as the common DB20/40 connector plugs, etc.) used by customers in the field into the entire PCB board, which is compact and easy to install. Help semiconductor equipment industry customers achieve the miniaturization of control modules, and reduce the labor cost of equipment installation and commissioning by means of prefabricated cables.

DYTP600A Food packaging industry

After nearly 20 years of development, food packaging machinery has formed a certain scale and become an important part of the machinery industry. At present, most of the packaging work of domestic food processing, especially the more complex packaging process is basically manual operation, which is very likely to pollute the packaged products, and this situation needs to be changed. Food packaging machinery is a collection of advanced technology of a variety of disciplines, with high efficiency, high precision, high automation and high flexibility, and is developing in the direction of intelligence and integration.

Valve island is one of the effective means of automation and mechanization of the production process, with high-speed and efficient, clean and safe, low cost and easy maintenance advantages, is widely used in the field of light industry machinery, in the food packaging and production process is also playing an increasingly important role. It has a large number of applications in all kinds of packaging machinery, which can shorten the processing auxiliary time, reduce the labor intensity of workers, and give full play to the efficient performance of the equipment.

In order to adapt to the increasing application trend of pneumatic and electronic control integration in food packaging plants, Deckwell has recently launched a multi-function valve island of the MTC series, which is also the company’s third generation valve island products. It not only uses lightweight composite materials on the main material, which is very suitable for the work scene such as the end of the manipulator with the requirement of product weight, but also combines the remote I/O module with the solenoid valve to realize the integration of the circuit module and the gas module. It is compatible with the mainstream PLC on the market, and has the characteristics of integration, modularity, high protection and rich diagnosis. As a whole, it meets the requirements of packaging industry customers for flexible assembly and convenient on-site use.

1 Year Warranty

1 Year Warranty