Deep cultivation process field, innovative software research and development

Chu Jian pointed out that “In the industrial field, especially in the transformation process of the process industry, including digital transformation, the application of AI, supply chain resilience, and sustainable development are closely related to software.” In the past 30 years, the company has been continuously breaking through, always focusing on the major needs of the industry, accelerating the development of industrial software, has established a rich product line, strong innovation strength, and independently developed a number of core industrial software such as APC, ISYS, PID, LIMS, EMS, SES, SCADA, OTS, AAS, RTO, APS, etc. Has formed a relatively perfect industrial software product pedigree.

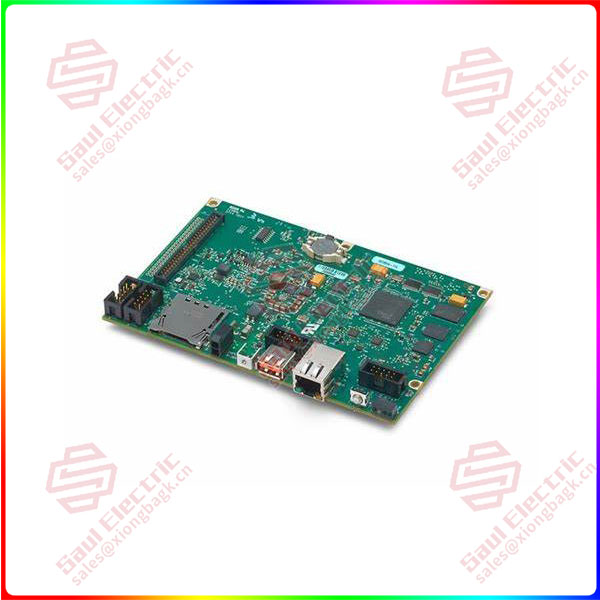

SCRIO-9627 In 2023, the domestic market share of the company’s advanced control and process optimization software (APC) was 28.2%, ranking first in the domestic market share for five consecutive years; The domestic process industry market share of manufacturing execution system is 20.7%, ranking first in the domestic process industry market share for two consecutive years; Operator Training simulation system (OTS) domestic market share of 14%, ranked first in the domestic market share for the first time.

Especially in the past few years, Zhongcong technology has increased its research in the field of basic software, such as the launch of the process industrial process simulation and design platform (APEX), which is a work of ingenuity to comply with the development of industry digitalization and intelligence and enhance competitiveness, and is of great significance to fill the gap in the basic software of domestic process industry, Chu Jian said, “After this achievement, We have more confidence to do some basic, core industrial software and industrial software that can represent the future.”

New “1+2+N” smart factory architecture

It is recognized by more and more enterprises

SCRIO-9627

In recent years, Zhongcong Technology continues to increase investment in software research and development, based on profound industrial practice and technical precipitation, adhere to customer needs, proposed a “1+2+N” smart factory new architecture – “1” represents a factory operating system, “2” represents two Automation. PA) and Business Automation (BA), where N represents N industrial APPs.

SCRIO-9627 The new architecture of “1+2+N” smart factory is a new architecture of smart factory created by deep insight into the core needs of process enterprises and combined with 30 years of industrial practice. It is not only a highly concise product technology and key capabilities of Zhongcong, but also the vision blueprint of Zhongcong technology for the digital transformation and intelligent development of customers in the industry. At present, the successful application and verification of this architecture has been reflected in more than 4,000 projects around the world, effectively promoting the construction of future smart factories in the process industry, and has won general recognition in the industry.

“We hope that through the new architecture of ‘1+2+N’ smart factory, focusing on the four core needs of process industry safety, quality, low carbon and efficiency, to create a real smart factory, of course, this is definitely an ecology, which requires all of us to work together.” Chu Jian said.

Based on the forefront of the industry to accelerate AI applications

At present, the company has built a core product system of “4 big data bases [(All-equipment Intelligent Perception Platform (PRIDE), all-process intelligent Operation management and control system (OMC), all-process intelligent quality monitoring platform (Q-Lab), Process industrial Process Simulation and design platform (APEX)] +1 intelligent engine”. To provide strong support for the realization of process industry smart factories, and help customers to achieve the high-quality development goals of “safety, quality, low carbon and efficiency”. Chu further said, “The four data bases include equipment data, production data, quality data and process simulation data, which combined with artificial intelligence will better help enterprises solve various problems.”

In the future, Zhongkong Technology will continue to strengthen the research and development and application of industrial software, consolidate the foundation of China’s industrial software self-reliance, provide customers with intelligent solutions of “AI+ safety”, “AI+ quality”, “AI+ low-carbon” and “AI+ efficiency”, and help the global process industry to transform from traditional manufacturing mode to highly automated and intelligent. Achieve high-quality sustainable development.

1 Year Warranty

1 Year Warranty