The fact that exports are greater than imports is another dimension of reversal.

International Federation of Robotics (IFR) data show that in 2023, China’s industrial robot exports hit a new high, reaching 118,300 units, while imports were only 82,400 units. After new energy vehicles, China’s industrial robots or set off the next round of sea peak.

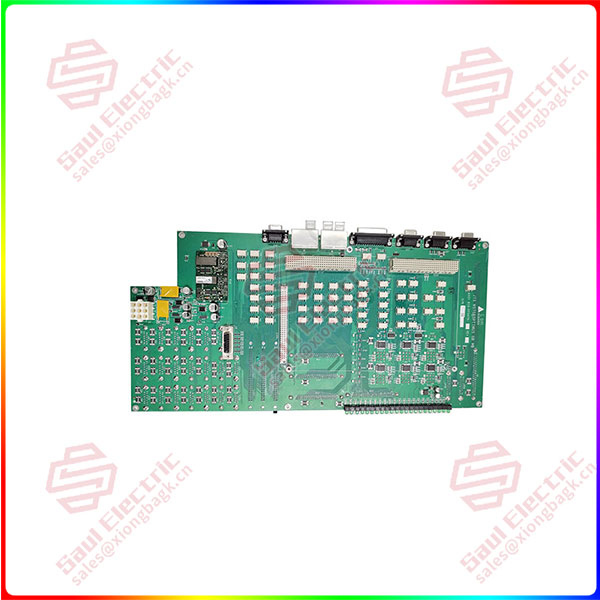

810-073479-215 Compared with other robot industrial parks in the country, the biggest feature of Wuhu is that the industrial chain is very complete, like a “hexagonal warrior”, Eft, asclepion and other machine localization rate of more than 90%, the local matching rate of more than 50%.

Wuhu robot industry was born out of Chery automotive equipment production line. In 2009, in order to reduce the maintenance cost of car building equipment, Efte and HIT cooperated to develop the first heavy-duty 165 kg spot welding robot in China.

Building ships in the 1950s, building cars in the 1990s, and building robots in the 21st century are based on Wuhu’s complete industrial categories – 39 of the country’s 42 industrial categories. This also means that industrial robots have a large number of application scenarios.

In 2013, Wuhu Robot Industrial Park was established, becoming the earliest national robot industrial park in China. The first phase of the industrial park is planned to be 5,000 mu, with 5 robot enterprises, hundreds of robots, and less than 400 million yuan of output value.

810-073479-215

Wuhu City is no stranger to how to develop new industries with a point and chain. Tang Zhehui, managing partner of An Yong Hui, pointed out that the development of Wuhu’s automobile industry has certain reference significance: actively introduce industrial talents to solve the problem of talent shortage at one stroke; Implement active industrial integration measures, introduce key technologies, purchase core equipment, and carry out industrial upgrading; Vigorously develop independent research and development capabilities, and establish independent and controllable core technology advantages.

At that time, the industry manager research found that the shortcomings and pain points of the robot industry lie in the core parts, the core parts occupy about 60% of the cost of the whole machine, to develop the industrial robot industry, we must first solve the research and development problems of the core parts, and at the same time, the four major families of international industrial robots are bigger and stronger, and the downstream is to do deep integration applications.

810-073479-215 Wuhu then took Efte as the leader, pulled up the entire industrial robot industry chain, and achieved technology accumulation through two methods of independent research and development and overseas mergers and acquisitions.

In 2015, Wuhu Aoyi fine machine Cable Company was established to integrate technical resources to focus on RV reducer. Eft has changed from a wholly-owned subsidiary of Chery to a mixed-ownership enterprise, and has acquired three foreign-funded enterprises, quickly making up for the technical shortcomings in the fields of robot spraying, grinding, polishing and so on.

Eft’s appeal to upstream industry chain enterprises appears. According to the demand of the industrial chain, Wuhu has attracted enterprises such as Philippe Power, Pumai Co and Qingneng Dechuang.

1 Year Warranty

1 Year Warranty