12kV VD4 circuit breaker intelligent production line

• In ABB Switch Intelligent Manufacturing Factory in Xiamen, the continuous flow production line of switchgear uses multiple industrial robots to complete shell assembly and realize continuous production of switchgear by beat and intelligent online detection;

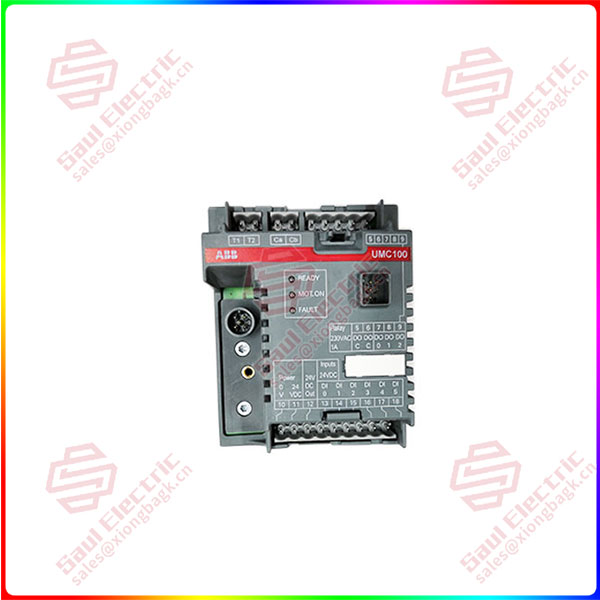

• Circuit breaker production line pole intelligent assembly system to achieve automatic pole assembly and tightening process effective control, production data online analysis, predictive maintenance of equipment, real-time early UMC100 warning and intelligent online detection;

Intelligent distribution, warehousing and pull production with the integration of agile networks and advanced planning and scheduling systems for automated three-dimensional warehouses and automated vehicle AGVs for raw materials, production processes and finished products; Accurate traceability of product quality throughout the life cycle;

• Establish refined customer management, from traditional passive services to predictive services and proactive services.

UniGear 500 flexible switchgear production line

ABB Switch in Xiamen widely uses different types of databases, knowledge bases and model libraries in business processes to improve process quality, efficiency and optimize operations, integrates the whole process information system to achieve cross-business value chain collaboration, and opens up the product life cycle, the whole production process and the whole supply chain. To realize the efficient coordination of “design – production – operation and maintenance”, “production, supply and marketing”, and “people and property”, to achieve the overall quality and efficiency of the factory while providing customers and other relevant parties with a better experience. According to public data such as the industry yearbook, Xiamen ABB switch has long been at the industry leading level in the indicators of efficiency and energy consumption level such as total labor productivity and 10,000 yuan output value. Through transformation and improvement, total labor productivity has shown double-digit growth in recent years, and energy consumption of 10,000 yuan output value has been further reduced by 30%.

UMC100

Automated stereoscopic warehouse

Intelligent manufacturing is the main direction of manufacturing power construction, and plays an important role in building a modern industrial system and realizing a new type of industrialization. In recent years, the state has issued two intelligent manufacturing capacity maturity standards and the “14th Five-Year” intelligent manufacturing Development Plan and other documents, and the construction of intelligent manufacturing demonstration factories and improve the maturity level of intelligent manufacturing capacity as an important starting point to achieve manufacturing transformation and upgrading. The model in the intelligent manufacturing standard specifies that the capability maturity level from low to high is level 1 (planning level), level 2 (specification level), level 3 (integration level), level 4 (optimization level) and level 5 (leadership level), whose level defines the stage level of intelligent manufacturing and describes the path of an organization to gradually move towards the final vision of intelligent manufacturing.

UMC100 Autonomous navigation distribution car

Based on this standard, the intelligent manufacturing Capability Maturity Assessment (referred to as “CMMM® Assessment”) is a set of authoritative assessment (or certification) system to assess enterprises to continue to improve the core capabilities of intelligent manufacturing, and level 4 is the highest rating actually carried out by this CMMM® assessment. The certification authority of “CMMM® Assessment” is the China Institute of Electronic Technology Standardization directly under the Ministry of Industry and Information Technology or its affiliated unit Beijing Saxi Science and Technology Development Co., LTD. As of May 2024, only more than 50 enterprises in China have obtained CMMM® Level 4 assessment. Xiamen ABB switches are the first in the transmission and distribution equipment manufacturing industry to receive this highest level of evaluation.

ABB Switch Co., Ltd. is the first joint venture of ABB Group established in China in 1992, providing 1 ~ 52 kV switchgear, circuit breakers and outdoor components products, medium voltage distribution digital solutions and product life cycle services. After more than 30 years of innovation and sustainable development, ABB Switch has developed into ABB’s largest manufacturing and innovation base in the world of medium voltage switches and one of the leading enterprises in the switch industry, which has been at the forefront of China and even the global industry in terms of digital transformation and green intelligent manufacturing.

1 Year Warranty

1 Year Warranty