The packaging industry has strict requirements for machine flexibility, high efficiency and fast maintenance. Machines need to adapt quickly to changes during production while keeping downtime low. Protecting operators from machine injuries is critical, so reducing downtime in installation, operation and maintenance is key. The machine shall work efficiently, reliably and safely upon delivery.

Manufacturers should design with automation and safety in mind, ensuring that machines comply with machinery directives and regulations to achieve sustainable production.

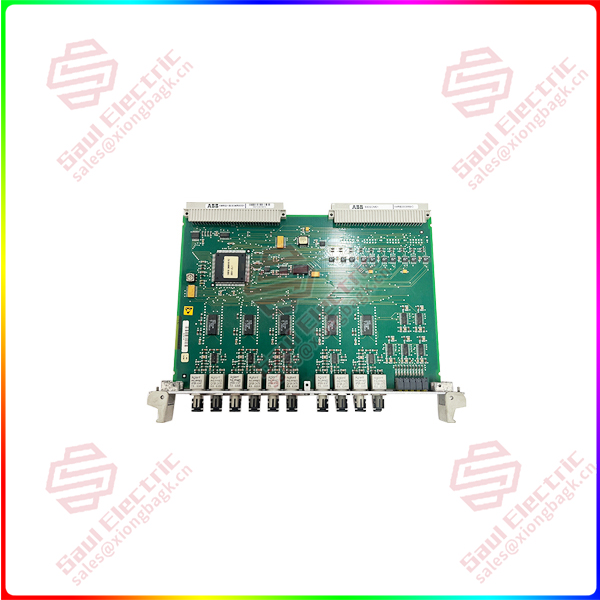

500SCM01 1MRB200059/C 1MRB15004R0001 Flexibility and connectivity are key

Faced with the diverse types of packaging machines on the market, Pilmagnetic offers comprehensive consideration and professional advice. Drawing on its expertise in safety design, mechanical protection and data protection, Pilmagnetic offers complete product solutions for the packaging industry, including safe paperboard feeding. In collaboration with customers, Pielmagneto develops automation equipment concepts covering mechanical safety and information security.

The overall safety solution from Peel Magneto uses a distributed structure that reduces cabling requirements and enables fast and secure communication between the PNOZmulti 2 secure small controller and built-in sensors. This solution is suitable for a variety of scenarios, whether used independently or in combination with advanced standard or motion controllers, providing a high degree of flexibility and adaptability on the production line or in compact equipment.

500SCM01 1MRB200059/C 1MRB15004R0001

What is the “role” of Pierre Magnet in the machine?

The role of Peel magnetic on the packaging machine is to ensure the safety of the entire operation. By providing a one-stop solution, Peel Magnetics brings together sensors, control technology products and software solutions to form a safety system that works together. These components can not only be assembled individually, but are also suitable for various packaging types in the packaging industry, including primary, secondary and terminal packaging.

The small controller PNOZmulti 2 plays a key role in this, connecting to the upper controller of the packaging machine and monitoring the signals of all the distributed sensors. This controller can send the safety status signal to the process controller in real time to ensure the safe operation of the whole system. PNOZmulti 2 also supports open communication, enabling communication with more advanced controllers via a standard fieldbus system.

500SCM01 1MRB200059/C 1MRB15004R0001 In addition, Peel Magnetic’s safe process protection system is equipped with the coded sensor PSENslock 2, which prevents unauthorized persons from entering hazardous areas, providing additional security. The PSENslock 2 has a locking force of 1000N, and the PNOZmulti 2 is responsible for its security monitoring.

In specific packaging applications, such as cardboard feeding, the PNOZmulti 2 can be used in conjunction with sensors to further ensure safety. If the number of cartons at the inlet falls below the set minimum, the PNOZmulti 2 automatically stops the dangerous movement, thus protecting the operator.

Safety and reliability are crucial factors in the automation of packaging equipment. When implementing automated machines, the combination of safety and security considerations is essential to ensure the effectiveness of the overall system and the safety of the operator. This is because information security and machinery safety are interdependent: without information security, machinery safety cannot be guaranteed; Without mechanical safety, people cannot get the protection they deserve.

Pilmagnetic provides the packaging industry with the right total solutions, which not only focus on the safe design of the machinery itself, but also include information security measures to ensure the safe operation of the entire automation system.

1 Year Warranty

1 Year Warranty