The ongoing demand for sustainability and greater efficiency has spurred innovation in the field of industrial automation. The Internet of Things enables the rapid integration of advanced technologies into industrial automation. Smart, fully connected factories enable manufacturers to improve process efficiency, safety and sustainability while reducing costs.

Security and maintenance are important for maintaining the functional state of infrastructure and equipment. Maintenance ensures industrial productivity, and regular maintenance leads to healthier and safer working conditions. Inadequate or lack of maintenance can lead to serious health problems and fatal accidents. This article delves into the ways in which iot sensors and software can work together to provide solutions that facilitate production maintenance and safety.

maintenance

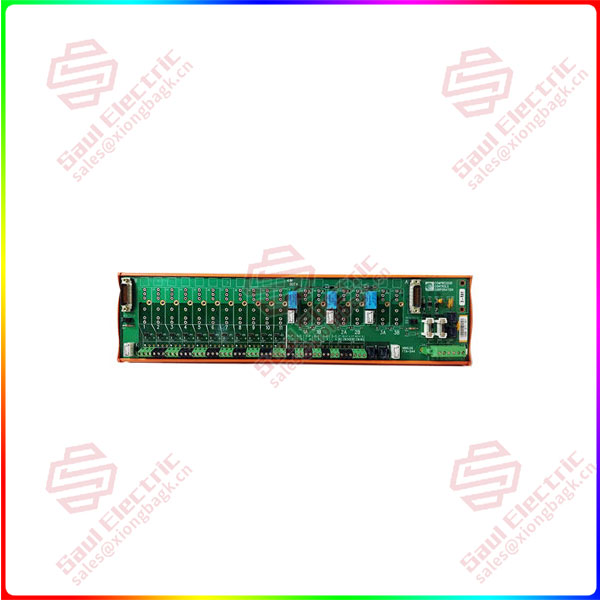

FTA-544 17-550544-001B Maintenance functions have evolved from responding to system failures, to planning, to forecasting, and finally (until now) to self-healing. Advances in operational sensor technology combined with the success of information technology have helped extract real-time performance data. These include cloud-based analytics and platforms, augmented reality (AR) and virtual reality (VR), all-inclusive planning or predictive maintenance, with negligible productivity losses.

Safety is crucial at all stages of production, such as design, manufacturing, installation, adjustment, operation, maintenance and final retirement. The Machinery Directive makes it mandatory for manufacturers to ensure that machinery and test equipment (for example, multimeters and thermal imagers) meet at least minimum safety levels. Machines and tools must meet the “essential health and safety requirements” listed in the directive and therefore need to provide a standard minimum level of protection.

How can iot contribute to factory safety and maintenance

Implementing iot solutions can radically improve operational efficiency. Iot improves machine efficiency by tracking performance and predicting failures in advance. In this way, unplanned downtime is eliminated. Industrial iot can also create a safer workplace. Industries investing in intelligent production and manufacturing systems want to achieve sustainable optimum production with minimal maintenance. This makes maintenance a top priority. Systems such as equipment condition based monitoring (CBM) or computerized maintenance management systems (CMMS), enterprise resource planning (ERP), and manufacturing execution systems (MES) perform maintenance activities in multiple industries.

FTA-544 17-550544-001B

These systems provide functions such as preventive and predictive maintenance, maintenance planning, maintenance scheduling, execution, traceability, and monitoring. E-alliance offers a wide range of maintenance, repair and safety products from leading brands. Keep your production floor, machinery and safety equipment well maintained with our wide range of components, tools and equipment. (For more product details, click here and here)

Device condition-based monitoring, predictive maintenance and iot

FTA-544 17-550544-001B Continuously monitor machine health in CBM by observing predefined device parameters. This reveals patterns that can be used to indicate device failure. CBM systems monitor equipment vibration, temperature changes, oil levels, motor voltage and current and other parameters. These measurements can be analyzed to generate an appropriate course of action.

Iot technology allows manufacturers and users to easily solve technical problems at a lower cost. Instrument sensors are now cheaper, more robust, more reliable, and offer a wider range of functions. Powerful wireless protocols allow actionable data from sensors to be collated into local gateways for immediate analysis and filtering. As shown in the figure below, this can then be transferred over the Internet to cloud computing resources that provide software as a service to users of all sizes. Such software can store data and perform all the necessary analysis to identify trends and identify potential points of failure.

Once these parameters are available for analysis, a fault model can be built to find deviations from these benchmarks. If you know a combination of parameter values that indicate a fault, setting up is simple. You can define a set of rules for failure conditions and use classical data analysis and mathematics to build the correct model. However, if the cause of the failure is not fully understood, then data science and machine learning will need to be used to develop algorithms that can spot important patterns in the data.

1 Year Warranty

1 Year Warranty