With the integration and development of digital technology and manufacturing industry in a wider range, deeper degree and higher level, digital transformation has become an important breakthrough to promote the high-quality development of manufacturing industry and accelerate the development of new industrialization. It is expected that during the “15th Five-Year Plan” period, the digital transformation of China’s manufacturing industry will usher in changes in many aspects, such as policy layout, supply and demand, innovative methods, technological evolution and transformation mode.

The Fifteenth Five-Year Plan period faces five changes

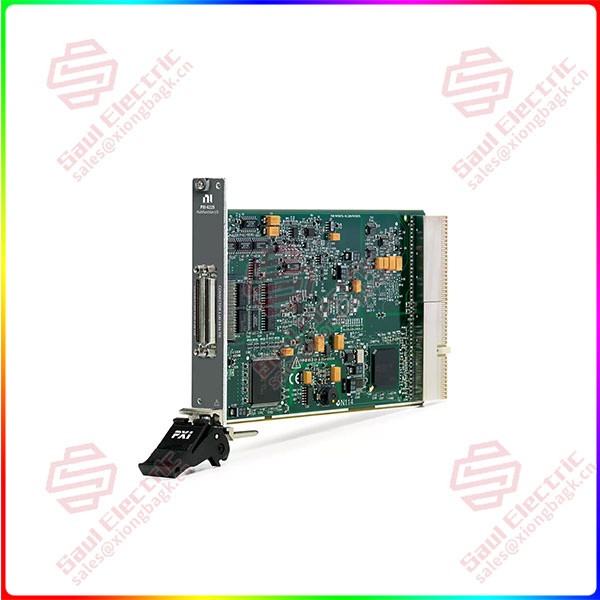

PCI-6225 From the perspective of policy layout, the digital transformation of manufacturing industry will face a transformation from “top-level planning” to “landing practice”. During the “14th Five-Year Plan” period, under the joint promotion of the state and local governments, the top-level design of the digital transformation of the manufacturing industry has gradually improved, and the roadmap and timetable have gradually become clear. On the one hand, the national level has carried out intensive deployment around the digital transformation of manufacturing industry; On the other hand, all localities and departments actively carried out policy deployment and implementation. It is expected that during the “15th Five-Year Plan” period, the policy system around the digital transformation of the manufacturing industry will continue to be refined, the forms of support will be more diverse, and various localities and industries will grasp the policy dividends, innovate and explore the formation of a series of replicable and easy to promote typical models and benchmark cases, give full play to the leading role of demonstration, and promote the digital transformation of the manufacturing industry.

From the perspective of supply and demand, the digital transformation of the manufacturing industry will face a shift from “short supply” to “supply and demand tend to balance”. During the “14th Five-Year Plan” period, the supply level of digital transformation services and the efficiency of supply and demand docking have been significantly improved. First, local governments will strengthen the cultivation of digital transformation service providers and the docking of service supply and demand. Second, the main enterprises of the manufacturing chain, digital platform enterprises, and basic operators have actively responded to the demand and innovatively launched high-quality digital solutions and products. It is expected that during the “15th Five-Year Plan” period, it will accelerate the cultivation of digital transformation service providers for the manufacturing industry, and emerge a series of miniaturized, fast, lightweight, and precise transformation solutions and products. Under the promotion of the local digital transformation supply and demand connection platform, a large number of replicable and promoted subdivision industry digital transformation typical models will be formed. The digital transformation of the manufacturing industry will reach a new level.

PCI-6225

From the perspective of innovation methods, the digital transformation of manufacturing industry will face a shift from “blood transfusion innovation” to “blood transfusion innovation”. During the “14th Five-Year Plan” period, the Party Central Committee made an important deployment to accelerate the implementation of the innovation-driven development strategy, and proposed to fight the war of self-reliance and self-reliance in high-level science and technology. It is expected that during the “15th Five-Year Plan” period, China will continue to deepen the innovation-driven development strategy, make new breakthroughs in strategic key areas related to national security and the lifeline of the economy, strive to form a number of domestic leading, industry-leading and international independent intellectual property product core technologies, and maximize the ability to control key core technologies.

PCI-6225 From the perspective of technological evolution, the digital transformation of the manufacturing industry will face a shift from a “closed system with soft and hard integration” to an “open system with soft and hard decoupling”. During the “14th Five-Year Plan” period, with the modularization and generalization of the basic hardware and components of the product, the automatic control system of the integration of software and hardware is constantly decoupling, evolving to an open system that can respond quickly to customer needs and has stronger flexible manufacturing capabilities, and the functions of a large number of personalized products are defined by software. It is expected that during the “15th Five-Year Plan” period, the “open system of soft and hard decoupling” will be more perfect, and industrial experience, laws, and knowledge will be precipitated into a callable and replicable mechanism model, which will be deeply embedded in various production equipment such as machine tools and robots, and jointly amplify the scope economy effect of personalized software and the scale economy effect of generalized hardware. Enable digital transformation of all kinds of manufacturing scenarios.

From the perspective of transformation mode, the digital transformation of smes will face a shift from “going it alone” to “chain transformation”. During the “14th Five-Year Plan” period, the government and enterprises jointly explored the formation of a “chain” transformation model with large and small, promoted cooperation between upstream and downstream enterprises in the industrial chain, and helped small and medium-sized enterprises speed up to find a digital transformation path. First, the national level continues to promote the “chain” digital transformation of smes. Second, around the aspects of technology empowerment, supply chain empowerment, platform empowerment, and ecological empowerment, a number of typical cases of “chain” digital transformation of smes have emerged. It is expected that during the “15th Five-Year Plan” period, more and more small and medium-sized enterprises will promote the “chain” digital transformation, the ecological model of “big with small and small” will gradually form, and the innovation chain, data chain, talent chain and financial chain will be accelerated. Large enterprises will help small and medium-sized enterprises on the chain to digitally improve process flow and quality management through the construction of “double innovation” bases and modern industrial chain parks.

1 Year Warranty

1 Year Warranty