In some applications, measurement technology is pushed to its limits. The directly reduced iron compaction process is one of them, because the temperature in the process is extremely high, and reliable measurement is almost impossible to achieve. Now, however, things have changed. The VEGAPULS 6X radar level meter has a new high temperature model, providing a pioneering solution for processes with temperatures up to 450°C.

Sponge iron

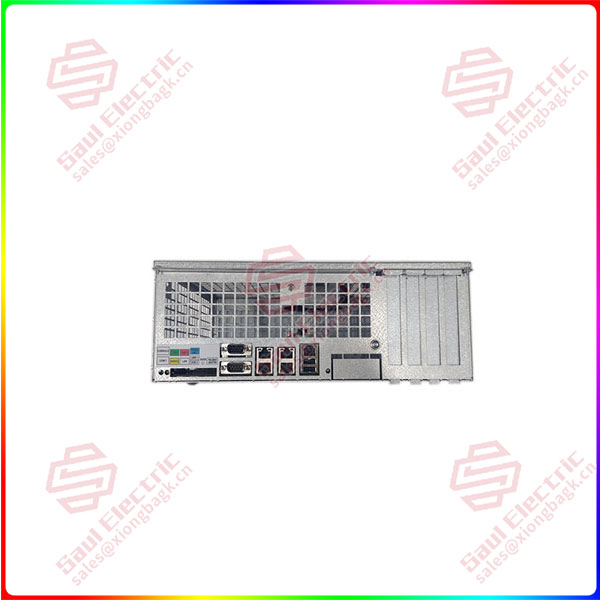

DSQC639 Direct reduced iron, also known as sponge iron, is an intermediate product of iron and steel smelting. In order to improve the economic efficiency of storage and transportation, sponge iron is often lumped. In this process, loose porous spongy pellets are processed at temperatures of 400°C or higher by high-temperature counterroll bulking machines.

A new solution to a universal problem

For many years, accurate sponge iron level measurement has been a difficulty in the process, and few measuring instruments can operate reliably under their conditions. Because in addition to high temperatures, iron’s low electrical conductivity also creates obstacles for measurement.

For such demanding applications, VEGA has created a small revolution with the newly launched high-temperature VEGAPULS 6X radar level meter. The meter is equipped with ceramic process isolation and a graphite seal to achieve previously unattainable heat resistance.

Ceramic process isolation, graphite sealing and more: Thanks to the innovative instrumentation construction, the radar level meter VEGAPULS 6X has significantly improved its measurement performance in high-temperature applications.

While it is true that hot stamping is a relatively rare process, there are countless special applications with the same extreme conditions, and these production processes require reliable measurement technology. There is no room for error in these processes, and since VEGAPULS 6X can overcome this measurement problem, it can handle all similar extreme conditions.

— Product Manager

DSQC639

Marvin Moser

Instrument performance to a new level

In order to significantly improve the measurement performance of the instrument in high-temperature applications, VEGA’s radar level meter is specially equipped with an innovative protective structure.

The combination of ceramic process isolation and graphite seal adds additional reliability to the measurement. By minimizing media adhesion on the antenna, the measuring capability of the instrument is greatly improved. The use of graphite as a seal makes the meter more durable. The result is a radar level meter that can withstand temperatures from -196°C to +450°C and pressures from -1bar to +160bar. It can handle even wild fluctuations in temperature with ease.

Tailored to the application

DSQC639 In addition to its ability to handle harsh operating conditions, the VEGAPULS 6X has advantages that are particularly critical for small containers. The meter not only offers a wealth of process connections, including compact threads and small flanges, but more importantly, it has no measurement blind spots. Therefore, it does not matter even if the process tank is fed directly to the top. In addition, the instrument adopts 80 GHz high-frequency radar technology, and the radar wave focusing ability is strong, which can effectively improve the measurement performance when the tank has internal components or stirring paddles; With its larger signal dynamic range, the VEGAPULS 6X is also able to reliably measure low dielectric constants that were previously unsuitable for radar measurements.

Can you rest assured of security?

Ensuring facility safety is one of the primary objectives of the process industry. To achieve this, VEGA has designed a complete safety package for the VEGAPULS 6X, which guarantees its safety even under harsh environmental conditions. In addition, the instrument covers a series of safety certifications such as network security, functional safety in accordance with the EU Machinery Directive, explosion-proof permits, and meets global safety standards and all prevailing norms. “With the launch of the VEGAPULS 6X high temperature model, we have set another milestone on the road to driving the development of safety technology.” Marvin Moser said with confidence.

1 Year Warranty

1 Year Warranty