ABB’s new IRB 7710 and IRB 7720 series of robots offer unprecedented flexibility with nearly 50 models and an even richer product portfolio

• Energy savings up to 30% [1]

• Suitable for industries such as automotive, general industrial and logistics

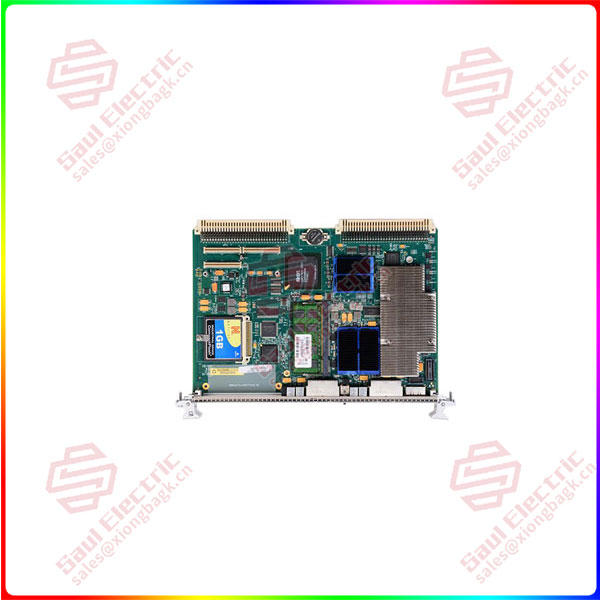

V7668A-1310B0 ABB Robotics has expanded its large robot portfolio with the launch of the new IRB 7710 and IRB 7720. These two new robots, together with the recently launched IRB 5710-IRB 5720 and IRB 6710-IRB 6740 series, bring a total of 46 different models with payloads ranging from 70 kg to 620 kg, providing unprecedented flexibility and a wider selection of robots. More excellent equipment performance will also fully help customers’ production operations.

“As companies introduce new technologies and equipment in order to increase productivity and achieve sustainability goals, we have designed a modular large robot family to provide customers with a more suitable selection of robots to help them conduct their business efficiently,” said Marcus Scone, global president of ABB’s robotics business unit. With the most comprehensive product portfolio on the market: mechatronics platforms, industrial robots, collaborative robots and autonomous mobile robots (AMR), the new family of large robots further expands our product line to help customers solve labor shortages while remaining competitive in a sustainable business model.

ABB’s new IRB 7710 and IRB 7720 robots come in 16 models and can be used in a wide range of industries. Users can choose the ideal model from a wide range of product lines to handle a wide range of applications in electric, hybrid and conventional vehicle production, including stamping, body in white, trolley battery assembly and vehicle final assembly. These robots are particularly suitable for high-load assembly applications such as integrated die-casting technology, high-speed presses and palletizing, as well as applications requiring high accuracy such as machining and friction stir welding.

V7668A-1310B0

The new robot with OmniCore™ control technology delivers best-in-class motion control, with path accuracy down to 0.6 mm, even when multiple robots are operating at speeds of up to 1600 mm/s and loads weighing up to 620 kg. A 25% reduction in beat time [1] further increases productivity and quality.

In the automotive industry, the new IRB 7710 robot with the OmniCore controller, coupled with a dedicated functional application module for stamping automation, can increase the output of robotic stamping lines from 12 strokes per minute to 15 strokes per minute, producing 900 parts per hour. In addition, in the construction industry, new robots will promote the development of modular buildings and improve the speed and quality of construction and surface treatment of steel structure building frames.

V7668A-1310B0 The energy-efficient design of the IRB 7710, combined with OmniCore’s regenerative technology, can save up to 30% of energy consumption [1], while a built-in power pack can return excess energy to the grid. To learn more about ABB’s modular large robot family, including the new IRB 7710 and IRB 7720, click on “Read More”.

[1] Operating data of the IRB 7710 compared to its predecessor, the IRB 7600, at the same 500 kg payload using the previous IRC5 controller.

1 Year Warranty

1 Year Warranty