Recently, the APL technology overall solution has been successfully applied in Jiangxi Tianxin Pharmaceutical Co., LTD. (hereinafter referred to as “Tianxin Pharmaceutical”) 09, 10 workshop automation upgrade project, and successfully produced products that meet quality standards, which is the first time the pharmaceutical industry introduced Ethernet-APL technology, This marks the success of the world’s first large-scale APL application project for a process industry master device. It has not only brought revolutionary changes to the production process of Tianxin Pharmaceutical, but also provided useful references for the intelligent upgrading of the entire pharmaceutical industry.

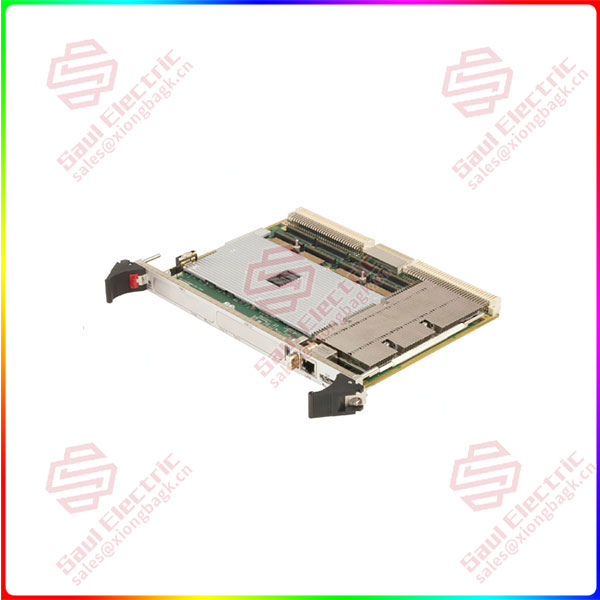

XVR19 6U-VME-SBC Tianxin pharmaceutical factory

Driven by the global wave of digitalization, the pharmaceutical industry is seeking a breakthrough in transformation and upgrading. As a leading enterprise in the field of vitamin production, Tianxin Pharmaceutical has been committed to improving production efficiency and product quality through technological innovation. China Control Technology and Tianxin Pharmaceutical have a deep cooperation history, since the two sides first joined hands in 2005, up to now, a total of 16 new automation or renovation project contracts have been signed. The two sides always uphold the goal of win-win cooperation, mutual trust and mutual respect, and work together to promote technological innovation and achieve business growth and development.

01

Target the core pain points of the pharmaceutical industry

In the traditional DCS control system scheme of the pharmaceutical industry, signal transmission mainly relies on copper core cables, but with the rise of copper prices and labor costs, the cost of cable bridge continues to rise. At the same time, factors such as the continuous expansion of the scale of control points and limited factory space have also brought many challenges to enterprises.

Tianxin Pharmaceutical adhere to innovation-driven, the courage to try, combined with the actual characteristics of the production site of the pharmaceutical industry, join hands with the central control technology to introduce Ethernet-APL technology, which has the advantages of fast communication speed, long communication distance, support high-power bus power supply, simple construction and maintenance, and meet the needs of explosion-proof. It has successfully solved the core problems of rising cost, difficult maintenance and low degree of data intellectualization.

XVR19 6U-VME-SBC

Tianxin Pharmaceutical project APL system framework

02

Multiple advantages demonstrate technological leadership

XVR19 6U-VME-SBC Central control APL technology overall solution, based on IEEE 802.3cg 10BASE-T1L standard (development of an Ethernet physical layer protocol specification specifically for process industries and similar environments), the application of ETHERNET-APL technology to access APL equipment to the control system. It realizes the unified access and management of APL intelligent instrument signals, traditional 4~20mA signals, digital switch valve signals, and wireless signals, and redefines the two-wire Ethernet physical layer communication technology of “communication + power supply” with the pioneer of “E network to the end”, perfectly solving the problems of field deployment, communication, and power supply.

The overall solution of APL technology has a series of significant advantages such as efficient data transmission, high-speed communication, high power supply, flexible and open network architecture, explosion-proof design, convenient maintenance, and intelligent diagnosis of the whole network. By defining two network segments, the main line and branch line, can support the simultaneous transmission of “data + power” within 1000 meters and 200 meters respectively. With a high communication rate of 10Mbps, it supports the barrier-free and reliable transmission of large amounts of data in potential explosion areas, providing strong support for accurate control and rapid response.

03

Industrial applications help customers succeed

Since the release of APL technology and test standards in 2019, the overall solution of APL technology has been successfully applied in many industries such as chemical, petrochemical and oil and gas, which strongly proves the reliability and practicality of Ethernet-APL technology, and also lays a solid foundation for its promotion in the pharmaceutical industry. Through the implementation of this project, Tianxin Pharmaceutical saves more than 70% of the cable cost, saves more than 90% of the area between cabinets, and significantly shortens the project construction period and reduces the construction cost.

The successful application in the 09, 10 workshop automation upgrade project of Tianxin Pharmaceutical is a breakthrough attempt of APL in the pharmaceutical industry, which has a significant milestone significance, and further proves the applicability of APL technology in the complex scene of the pharmaceutical industry, which helps the continuous improvement of APL product system. Promote the development of Ethernet-APL technology in the pharmaceutical industry and even the entire field of industrial automation.

1 Year Warranty

1 Year Warranty