Rockwell Automation, one of the world’s leaders in industrial automation, informatization and digital transformation, announced the addition of GenAI prescriptive-work orders to its Fiix Asset Risk Predictor software, creating its first fully predictive and regulated maintenance solution to help manufacturers eradicate unplanned downtime.

PXI-2567 Fiix Asset Risk Predictor’s powerful AI takes as little as two weeks to put to use and enables early asset failure prediction. With the addition of Fiix specification maintenance, the Fiix Asset Risk Predictor can leverage GenAI to turn failure predictions into detailed work orders that can be acted upon by the maintenance team. Work orders are generated with reference to asset data, completed work orders, and trusted maintenance sources. Based on this, the maintenance operations team can further review and edit the work order, and then dispatch the work order via instant push to any computerized maintenance management system (CMMS) or Enterprise Asset management (EAM) tool. All data will remain completely private and protected by high security standards.

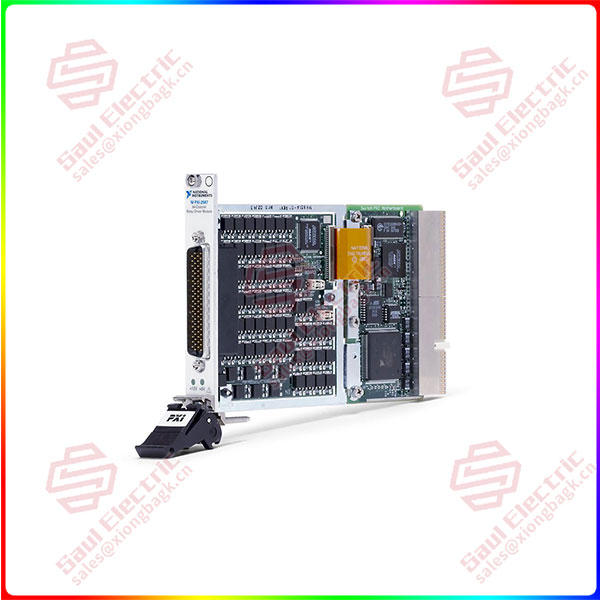

PXI-2567

“With Fiix specification maintenance, users can turn asset data into the predictive content and work orders they need to dramatically reduce unplanned downtime, increase operating equipment efficiency, and maximize the value of their resources.” “In addition, it balances the range of product maintenance knowledge of employees who are just starting their careers with those who have decades of experience with the company,” said Sandy D ‘Souza, senior sales director for Rockwell Automation Fiix Americas. Everyone has access to detailed asset and work order information.”

PXI-2567 Fiix Asset Risk Predictor integrates predictive maintenance with AI technology and actionable GenAI workorders, ensuring manufacturers can see results as promptly as possible.

Fiix Specification maintenance is not only incorporated into the Fiix Asset Risk Predictor, but can also be purchased and used separately from the Fiix CMMS; It also integrates seamlessly with the system. In fact, it can be smoothly integrated into the CMMS or EAM used by different companies.

1 Year Warranty

1 Year Warranty