The TS 7 conveyor system moves large and heavy battery components safely and reliably during the assembly process.

With the NEXO wireless tightening gun and OPEX torque wrench, Bosch Rexroth guarantees a high degree of freedom, process reliability and precision for kit assembly, meeting all the requirements of VDI/VDE 2862 for safety-critical tethers.

8102-HO-IP Efficient cartesian robot with open interface

As a more cost-effective and complete solution for battery module and pack assembly, Bosch Rexroth offers cartesian-coordinate robots for typical applications such as cell module or pack handling, tightening or dispensing. High mechanical strength and repeatability throughout the work area are essential for many processes. In order to reduce cycle time, several processes, such as the tightening process, can also be replicated simultaneously on the cartesian robot.

8102-HO-IP

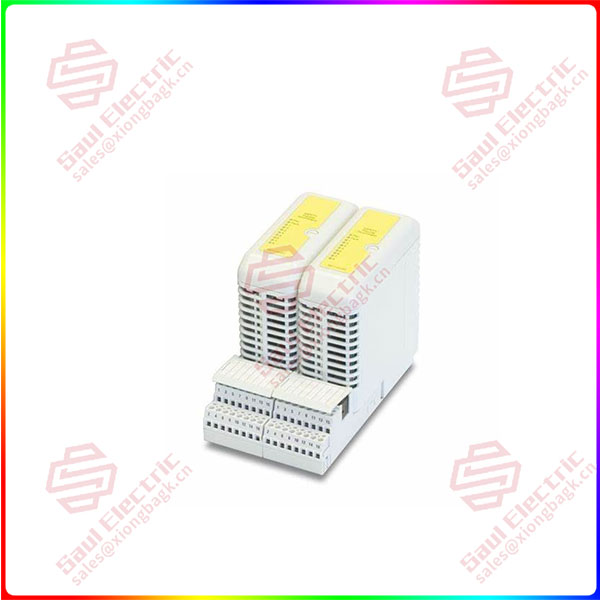

8102-HO-IP Bosch Rexroth’s cartesian robot is a complete mechatronics package with the option of pre-installed operating software. They can therefore be quickly debugged, sequenced, and connected to higher-level full-line control systems. Open interfaces for connection to various end actuators, such as clamps or distributions, ensure maximum flexibility.

Open solutions: Bosch Rexroth’s mechatronics system for cartesian robots connects a variety of end actuators in a variety of applications through an open interface.

Bosch Rexroth offers durable linear guides for drying chambers with the optional integrated measurement system IMS, as well as ball screw drive system components, electric cylinders and complete press systems for stamping and connecting applications.

Bosch Rexroth’s complete automation portfolio for battery production covers electrode and battery production as well as tailline testing and recovery discharge processes.

1 Year Warranty

1 Year Warranty