A comprehensive automation portfolio for the entire value stream

• One-stop component, module and system level solutions

• Cartesian robots and many other economical solutions

Efficient battery assembly with fast and accurate cartesian robots.

MVR1600-4601 The demands of battery production are changing rapidly. In response, Bosch Rexroth offers equipment and system manufacturers a wide range of components and systems for the entire value stream, making the value stream more economical and efficient. A broad, flexible automation portfolio with open digital network interfaces is the key to short cycles, low production costs and a high degree of flexibility. Bosch Rexroth’s product portfolio covers individual components, system solutions and subsystems in the field of linear systems, connected systems and transmission systems technology, as well as the comprehensive AUTOMATION system ctrlX AUTOMATION.

Electric vehicles, electronics, and building technologies require more energy storage than ever before. Bosch Rexroth contributes to the development of this sector with its comprehensive and specialized knowledge of production processes, years of experience and a broad portfolio of automation products and global services.

MVR1600-4601

The Bosch Rexroth battery production portfolio includes individual components, system solutions and subsystems in the field of linear systems, connection systems and transmission systems technology, as well as the fully open AUTOMATION system ctrlX AUTOMATION. IT crosses the traditional boundaries between machine control, the field of IT, and the Internet of Things. With real-time operating system Linux, consistent open standards, programming technology, web-based engineering and all-inclusive iot connectivity, ctrlX AUTOMATION can reduce component and engineering costs in battery production by 30% to 50%.

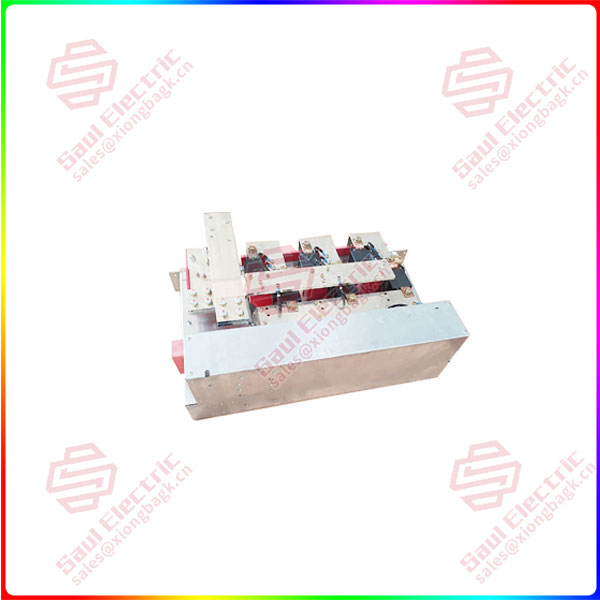

MVR1600-4601 With the help of a broad portfolio of hardware and software solutions, various solutions can be implemented and networked across the entire value stream. ctrlX CORE is the core of the automation system and the link between automation technology, connectivity technology and material handling. DRIVE System ctrlX DRIVE complements the battery production solution portfolio with compact and modular servo drives and servo motors.

Material handling includes system solutions such as FTS flexible conveying system solutions for conveying and precise positioning of materials and workpieces in cell manufacturing, and VarioFlow chain conveying system solutions for highly automated and confined Spaces. The TS 2 Booster delivery system shortens cycle times with fast, short transfers.

The TS 5 and TS 7 conveyor systems are designed to transport the heaviest loads in harsh module and kit assembly environments. Its design is particularly robust, and its low-maintenance drive design concept ensures a high operating rate. ACTIVE Shuttle, an autonomous mobile robot, delivers battery packs and other components, as well as materials, within the facility on a periodic basis and on demand.

1 Year Warranty

1 Year Warranty