In the current environment, high availability production relies on automation solutions that are efficient, fast and easy to implement. Using single-axis and multi-axis applications as a model, Bosch Rexroth shows how this can be achieved in practice.

Whether it’s reducing CO2 emissions, optimizing supply chains, addressing shortages of skilled workers, or developing new business areas, the challenges facing mechanical engineering are diverse. These challenges not only affect the design process, but also the choice of suppliers. To capture the linear drive technology market, you must be able to provide targeted solutions to the pressing problems in the field of automation. The most important question is: how do you perform typical motor tasks as quickly and efficiently as possible?

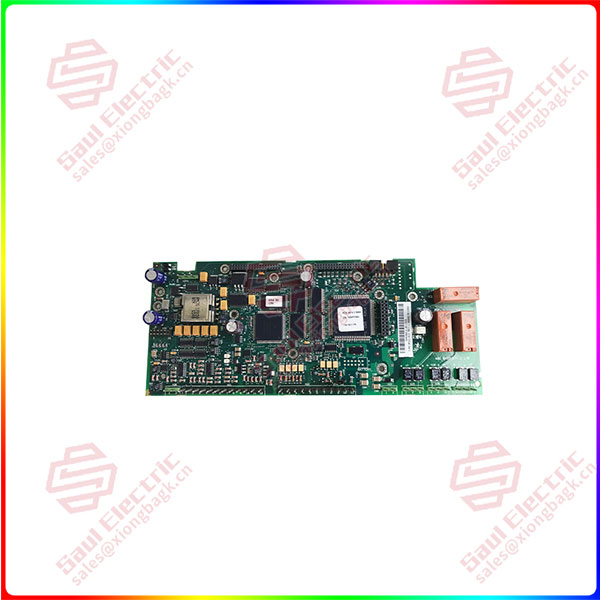

RMIO-01C Perform various tasks easily

In the field of automation, linear transmission technology can be easily applied to a variety of different tasks. They are used for a wide range of tasks, including picking, placing, feeding, distributing, positioning, separating, stacking, and even assembly, tightening, and testing. However, machine or system manufacturers cannot easily select individual components from a catalog and then configure and coordinate them. Therefore, we need an intelligently connected portfolio that can digitally select, design and fully configure single-axis, actuator and multi-axis systems. If necessary, these portfolios should also include motors and drive controllers, and even complete intelligent subsystems with software.

RMIO-01C

The configurable linear axes of Bosch Rexroth help solve motion tasks and greatly simplify the steps involved in the engineering work.

The fast way to a high-availability production line

RMIO-01C Bosch Rexroth offers a modular construction system that includes linear shafts, drive systems and software solutions. Automated processes in the industry will be faster and simpler than ever before. Whether feeding, transferring, palletizing, or loading and unloading, all of these process steps can be performed in a very economical manner with the help of various linear axes.

Fast auomation on demand: In the Bosch Rexroth product portfolio, linear shafts cover a wide range of applications and are easy to digitally configure and install. Optional automation packages and pre-installed Smart Function Kit software speed up the commissioning and sequencing process.

Economical linear module for handling small parts

Given the wide range of motion requirements, different linear axes can be used for each process step. For example, in Bosch Rexlot’s SMS portfolio (compact lead screw drive modules), a small and compact handling shaft is sufficient to feed, transfer or clamp a pallet of small parts in a relatively slow cycle time. Small modules with ball screw assemblies designed for handling small parts, with lightweight aluminum as part of the linear guide, are especially space-saving. Available in five sizes (30, 40, 50, 80 and 120), typical loads of less than 1 to 22kg can be moved efficiently and cost-effectively over distances of 1200mm. As an ideal alternative to pneumatic equipment, the ultra-compact linear shaft also saves energy and reduces maintenance costs.

1 Year Warranty

1 Year Warranty