ABB, the world’s leading supplier of industrial automation and power technology, has officially launched its latest IMHSS03 hydraulic servo module. Designed specifically for turbine speed control, this high-performance module integrates a servo valve or servo motor with a controller for precise speed and position control, bringing a new solution to industrial automation.

Excellent performance, precise control

The IMHSS03 hydraulic servo module provides unprecedented speed and position control accuracy with its high-resolution analog-to-digital and digital-to-analog converters. It uses advanced control algorithms and optimized design to quickly respond to external inputs and commands to achieve fast dynamic adjustment and tracking. In addition, the module also supports a wide range of speed regulation, which can be flexibly adjusted according to different application requirements to ensure that the system is always in the optimal working state.

Safety features, escort

Safety is a primary consideration in the field of industrial automation. The IMHSS03 hydraulic servo module is built with complete safety features to monitor system anomalies in real time and trigger emergency shutdowns or other safety measures if necessary. This highly integrated safety design ensures the stability and safety of the production process and provides a strong guarantee for the continuous operation of the enterprise.

Work together and integrate efficiently

IMHSS03 hydraulic servo module not only has excellent performance, but also has strong collaborative work ability. It can exchange data with other devices, such as upper-bit systems or other control modules, to achieve seamless integration and efficient collaboration of the entire system. In the INFI 90® system, the IMHSS03 module is connected to the IMMFP01, IMMFP02 or IMMFP03 multifunction processor module (MFP) to jointly control the position of the steam or gas turbine throttle, thus achieving precise control of the turbine speed.

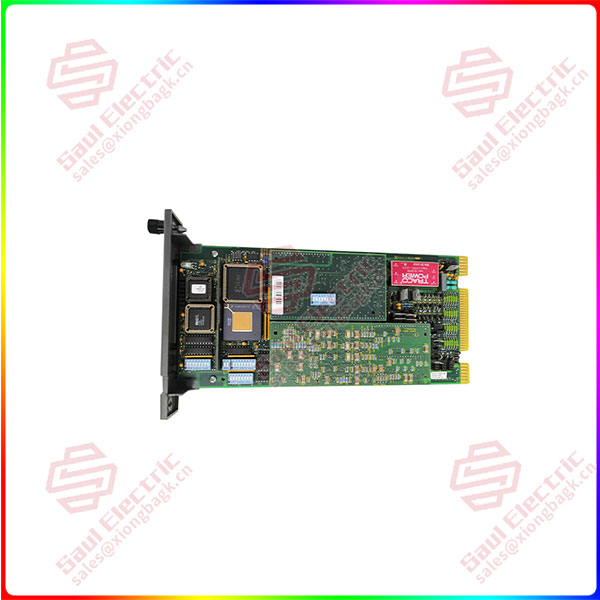

IMHSS03

Enhance features and enhance the experience

Compared to its predecessor, the IMHSS03 hydraulic servo module has been significantly enhanced in several aspects. It not only has higher resolution of analog-to-digital and analog-to-digital converters, but also provides more precise LVDT signal conditions and an improved I/H converter interface. In addition, the module has the ability to automatically adjust the demodulator gain to further improve the response speed and stability of the control loop. At the same time, redundant LVDT interfaces and servo valve outputs are designed to provide users with more operational choices and higher system reliability.

Programmable and compatible, flexible application

IMHSS03 hydraulic servo module supports user-defined control program writing and debugging, and complex control logic can be easily realized through programming software. In addition, the module also has strong compatibility and can be connected and communicated with a personal computer to achieve remote monitoring and data processing. This flexibility enables the IMHSS03 module to be widely used in a variety of industrial automation and control systems, such as machine tools, robots, conveyor belt systems and printing presses, providing strong support for the production efficiency and accuracy of enterprises.

Conclusion

The release of the IMHSS03 hydraulic servo module marks another important milestone for ABB in industrial automation. This high-performance, highly reliable module not only revolutionizes turbine control systems, but also injects new vitality into the development of the entire field of industrial automation. We have reason to believe that in the coming days, IMHSS03 hydraulic servo module will play a more important role in the field of industrial automation with its excellent performance and wide application prospects.

1 Year Warranty

1 Year Warranty