General Electric (GE), the world’s leading manufacturer of industrial automation and power equipment, announced the launch of the IS210BPPCH1AEC, a high-performance pressure sensor designed specifically for the oil and gas industry. With its high precision monitoring, remote monitoring, data analysis and durability, the sensor shows great potential to improve the safety and efficiency of oil and gas production processes.

High precision monitoring to ensure production safety

The IS210BPPCH1AEC pressure sensor provides accurate pressure readings, which are critical for the oil and gas industry where precise control and real-time monitoring is required. In oil and gas Wells and complex pipeline systems, accurate pressure data is the key to ensuring production safety and preventing accidents. The sensor’s high-precision monitoring capability enables operators to keep track of production conditions in real time and take timely measures to deal with potential risks.

Remote monitoring to improve operational efficiency

In addition to high-precision monitoring, the IS210BPPCH1AEC also has a powerful remote monitoring function. Through the remote monitoring system, the operator can track the status of the device anytime and anywhere, and discover and respond to potential problems in a timely manner. This ability to monitor and respond quickly not only reduces risk in the production process, but also significantly improves operational efficiency. At the same time, the remote monitoring function also makes equipment maintenance more convenient, reducing downtime and maintenance costs.

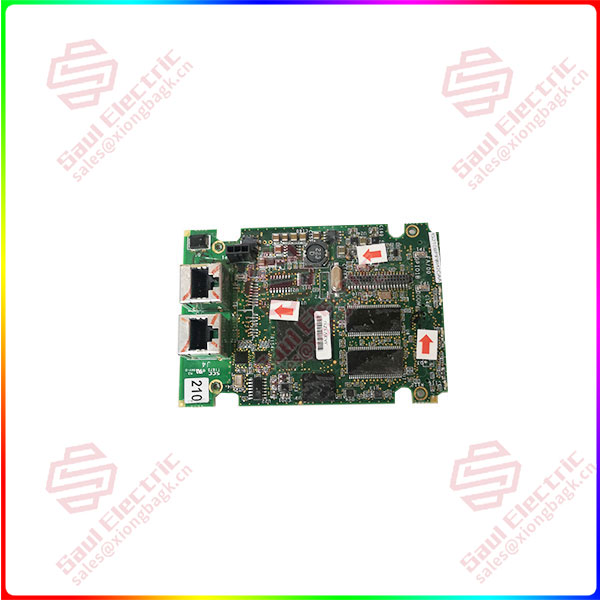

IS210BPPBH2CAA

Ability to analyze data and optimize work flow

The IS210BPPCH1AEC pressure sensor not only records data, but also analyzes trends and patterns. Through in-depth analysis of the data, operators can understand the changes in the production process and potential problems, so as to optimize the work process and improve production efficiency. This data analysis capability provides strong support for the intelligent upgrading of the oil and gas industry and promotes the sustainable development of the industry.

Strong durability, adapt to harsh environment

Working conditions in the oil and gas industry are often harsh, including high temperatures, pressures and corrosive substances. The IS210BPPCH1AEC pressure sensor has been designed with these factors in mind, using high-strength, corrosion-resistant materials and processes to ensure stable operation in harsh environments. This high durability makes the sensor promising for a wide range of applications in the oil and gas industry.

Conclusion

The release of the IS210BPPCH1AEC high performance pressure sensor is another important result of GE’s technological innovation in industrial automation. With its high precision monitoring, remote monitoring, data analysis and durability, this sensor provides a strong guarantee for safe and efficient production in the oil and gas industry. With the continuous development of the oil and gas industry, GE will continue to be committed to technological innovation and product optimization, and contribute more to the intelligent upgrading of the industry.

1 Year Warranty

1 Year Warranty