The GE IS200EROCH1A is an excitation protection controller manufactured by General Electric (GE) designed for gas turbine excitation systems to protect the excitation circuit from failure damage. The device has a variety of protection features, including over voltage, over current, under voltage, under current and speed change protection, to ensure the safe operation of the excitation circuit. It uses specified diagnostic functions to ensure the high reliability of the product, and provides a human-machine interface and object manipulation for easy user operation.

IS200EROCH1A has RS232, RS485, Ethernet and other communication interfaces, the power supply is 24V DC, its size is 483mm × 320mm × 210mm, the weight is about 20kg. The product is widely used in gas turbine systems in power plants, compressor and pump excitation systems in the oil and gas industry, reactor and separator excitation systems in the chemical industry, and other industrial applications such as fan and pump excitation systems.

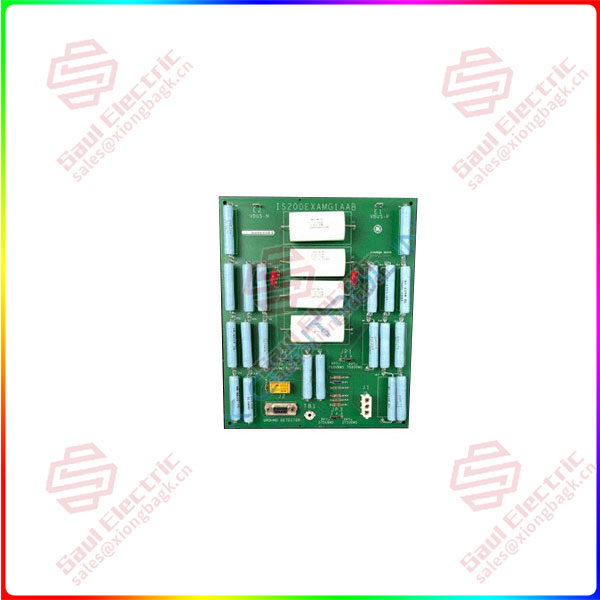

IS200EXAMG1A

General Electric (GE) is a multinational industrial and technology services company founded in 1892 and headquartered in Westport, Connecticut, United States. With a wide range of businesses, including aviation, power, healthcare, transportation, oil and gas, renewable energy, construction and financial services, GE is one of the world’s largest industrial companies with more than 300,000 employees.

The IS200EROCH1A, part of the GE EX2100 series, is an excitation regulator TAB with data transfer capability that can be connected to two locations on the regulator rack. The module is designed to support regulator options, third-party GE ground detectors, and terminal board power connections. In addition, the IS200ERGTH1A model can be connected to the IS200EROCH1A module to detect ground resistance leakage of the generator’s excitation current. With two backplane connectors, four high-voltage electrolytic capacitors and a CPU socket, and a keyboard connector designed to connect RS-232 cables, this module provides a flexible solution to meet the data transmission and communication needs of industrial control systems.

1 Year Warranty

1 Year Warranty