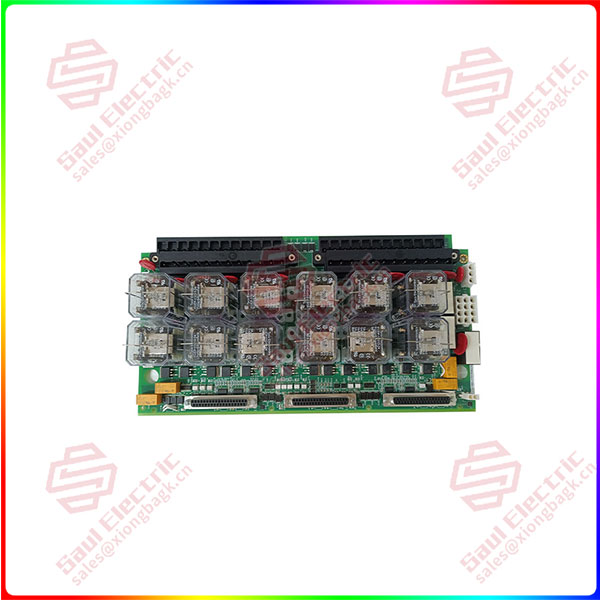

General Electric (GE) recently introduced an important industrial automation component, the IS200TREGH1B. This module is an emergency trip relay board designed for the Mark VI series gas turbine control system, which is mainly used to quickly cut off the gas supply in emergency situations to protect equipment and personnel.

The IS200TREGH1B module has power outputs for multiple emergency trip coils and uses relay contacts to control the emergency trip loop. It typically accepts 125 VDC input voltage, depending on the system configuration, and supports DIN rail or panel mounting. The module has been designed with the application needs of industrial environments in mind, with high reliability and durability, in line with relevant power industry standards and safety specifications.

IS200TREGH1BEC

In addition, the IS200TREGH1B module is known for its high efficiency, fast response and safe design. It uses industrial-grade chips to ensure reliable operation in emergency situations and has multiple protection features to ensure safe system operation. The modular design also makes the installation and maintenance process easier.

The IS200TREGH1B’s emergency trip function is critical in the event of a failure or abnormal situation, quickly shutting off the gas supply, preventing an extended incident, while protecting critical equipment such as gas turbines from damage, and ensuring personnel safety. This module is not only widely used in gas turbine control system, but also in other industrial process control fields.

Applications include power plants and substations in the power sector, petrochemical process production, and a variety of other industrial processes. The introduction of this module further enriches GE’s product line in the field of industrial automation control systems and provides strong support for improving production efficiency and ensuring industrial safety.

1 Year Warranty

1 Year Warranty