ABB recently introduced the ACU-01B sealing control unit model 3HNA024871-001, which has attracted much attention in the field of industrial automation due to its high efficiency, high precision, safety, reliability and programmability. This control unit is mainly used in the sealing system control of spraying robots, using advanced sensor technology and control algorithms, which can accurately monitor and control the sealing state, ensure that the paint does not leak, while protecting the environment.

The ACU-01B 3HNA024871-001 control unit supports a variety of communication protocols, such as Modbus RTU, Profibus DP, DeviceNet and Ethernet IP, and can easily communicate and exchange data with other devices to achieve seamless integration of industrial automation systems.

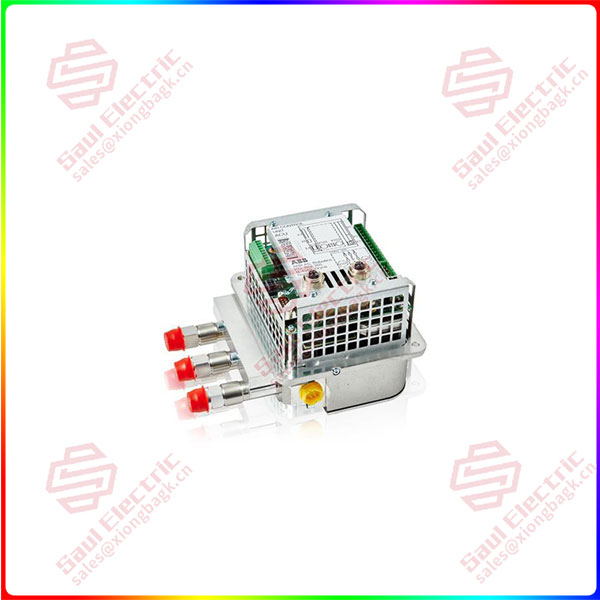

ACU-01B 3HNA024871-00103

In addition, the module is able to operate in the temperature range from -10°C to +50°C, and the humidity range is 5% to 95% non-condensing, providing good environmental adaptability.

In terms of specifications, the 3HNA024871-001 control unit has a flow range of 0-1000 L/min, an accuracy of ±1%, a response time of 100ms, and uses RS-485 as a communication interface. With a size of 100mm×100mm×50mm and a weight of 500g, it is suitable for a variety of gas types, including air, inert gases, plateau gases and high pressure gases.

The product model also includes the spare parts model 3HNA024871-0012-01, showing that ABB offers a variety of options to meet different customer needs. When maintaining and upgrading robotic systems, these spare parts ensure the continuous operation and performance optimization of the robot.

1 Year Warranty

1 Year Warranty