Bently Nevada, Inc., a leading provider of industrial monitoring and protection solutions, recently introduced its newest product, the 3500/53 133388-01 Electronic Overspeed Detection module. This module is part of the 3500 Series Mechanical Inspection system, designed for mechanical overspeed protection, providing highly reliable and responsive speed monitoring.

The main functions of the 3500/53 133388-01 module include real-time monitoring of the rotational speed of the rotating equipment and immediately sending an alarm signal once the rotational speed of the equipment exceeds the preset safety threshold, thereby preventing potential equipment damage or safety incidents. The module can receive signals from eddy current sensors or magnetic sensors with input signals ranging from +10.0V to -24.0V, ensuring accurate monitoring.

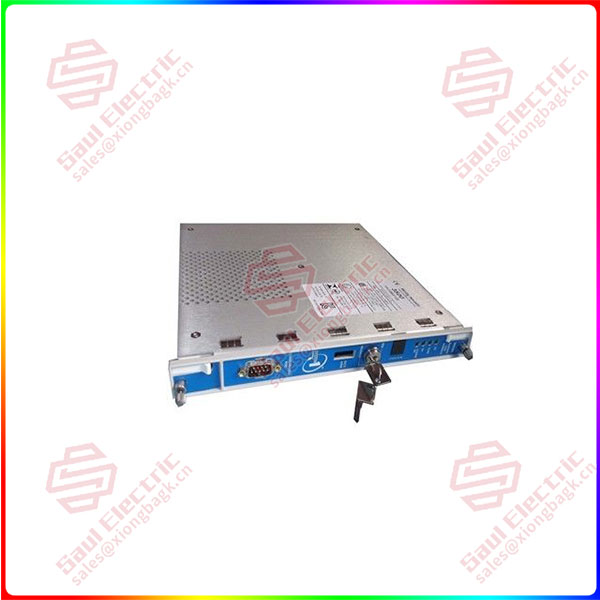

3500/53 133388-01

In addition, the 3500/53 133388-01 module is designed with the harsh conditions of the industrial environment in mind and adopts industrial grade standards for high reliability and stability. The module is easy to install and can be integrated directly with Bently Nevada’s other devices, providing a variety of alarm and data output methods to meet different application requirements.

3500/53 133388-01 module has been widely used in many industrial fields, including power, petrochemical, iron and steel metallurgy, etc. It can real-time monitor the speed of key equipment such as steam turbine, compressor, pump and so on, to ensure that the equipment operates in a safe speed range, to avoid equipment damage or safety accidents caused by overspeed. It provides a strong guarantee for the smooth progress of industrial production.

As industrial automation and intelligent manufacturing continue to deepen, Bently Nevada’s 3500/53 133388-01 modules are expected to play an important role in enhancing the safety and efficiency of industrial systems, further consolidating Bently Nevada’s leadership in industrial monitoring and protection.

1 Year Warranty

1 Year Warranty