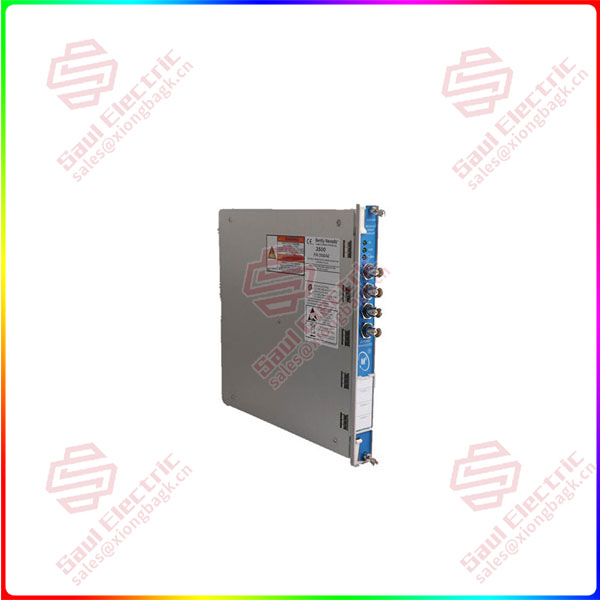

Bently Nevada recently announced a new 3500/42M 140734-02 vibration monitoring module, further enhancing its product line in the field of industrial monitoring and control systems. This module is designed to continuously monitor the vibration and position information of rotating machinery equipment, providing high-precision measurements and user-programmable alarm Settings.

Product features:

Multi-channel monitoring: 3500/42M 140734-02 is a four-channel vibration monitoring module capable of accepting input from precursors and seismic sensors and adjusting the signal to provide multiple vibration and position measurements.

3500/42M 176449-02

User programmable: Users can program each channel through 3500 Rack Configuration Software to monitor and report parameters including radial vibration, thrust position, differential expansion, eccentricity, REBAM, acceleration, speed, shaft absolute value, and circular acceptance area.

High Precision measurement: This module provides accurate vibration and position measurements to help prevent failures and optimize performance.

Reliability and durability: Designed to meet the harsh requirements of industrial environments, ensuring stable operation under extreme conditions.

Application field:

The new 3500/42M 140734-02 module is suitable for use in petrochemical, power, metallurgy, water treatment and shipbuilding industries, especially where high reliability and precise control are required, such as pumping stations, fans, compressors and ship’s main propulsion systems.

Market feedback:

The market has responded positively to the launch of the 3500/42M 140734-02 module, with users appreciating its high degree of automation, accuracy, reliability and wide range of applications.

1 Year Warranty

1 Year Warranty