In the field of industrial automation, precise and reliable control is the key to ensuring production efficiency and safety. GE today announced the introduction of the new IS200TRLYH1BHH relay output module, which will provide powerful relay output for distributed control systems (DCS) and programmable logic controllers (PLCS).

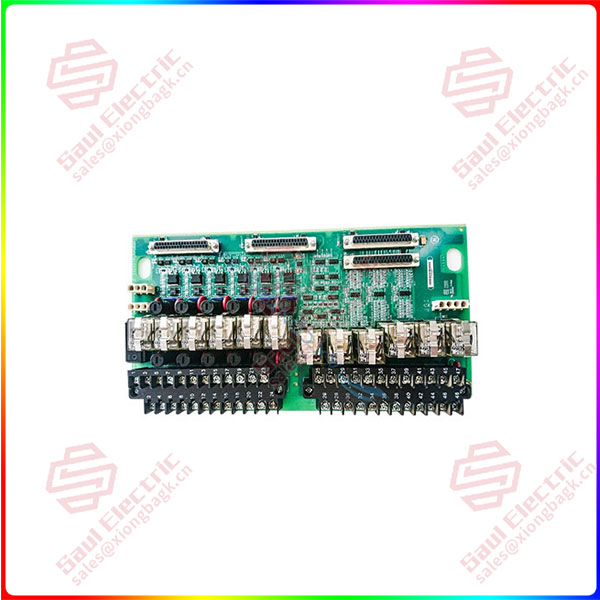

The IS200TRLYH1BHH is a relay interface module designed for industrial control systems and is widely used in GE’s Mark VI and Mark VIe series turbine control systems. By providing a digital output signal, this module can control various external devices, such as pumps, valves and alarms, enabling precise process control.

The main features of this module include:

Type: Relay output module

Input voltage: Usually 24VDC, installation requirements may vary

IS200TRLYH1B

Output configuration: Multiple relay outputs can be configured for different functions

Number of outputs: Usually 8 or more relay outputs

Isolation: There is current isolation between input and output, which enhances the safety and reliability of the module

Signal type: Digital signals used for control and monitoring

Mounting method: Support DIN rail or panel mounting

Environment level: Designed for harsh industrial environments. For specific environmental conditions, refer to the product documentation

Communication protocols: Communications are typically conducted through GE’s proprietary protocols

The introduction of the IS200TRLYH1BHH module not only enhances GE’s product line in industrial automation, but also provides new options for industries that require high-reliability control solutions. The module’s high isolation level and powerful output configuration make it ideal for power generation facilities, process automation, system monitoring and security systems.

1 Year Warranty

1 Year Warranty