In the field of industrial automation, safety and efficiency are the two core concerns of enterprises. To this end, GE recently introduced a new digital output module, the IS230TNRLH1B, which provides a new solution for critical applications in industrial automation and process safety with its high reliability and powerful features.

The IS230TNRLH1B module is part of the GE Mark VIe Safety Instrumentation System (SIS) and is specifically designed to control various process elements in safety-critical environments such as oil and gas, petrochemicals, and power generation. The module offers 16 digital outputs of the type of digital relay and supports output ratings including 24V DC, 120V AC and 240V AC, depending on the configuration.

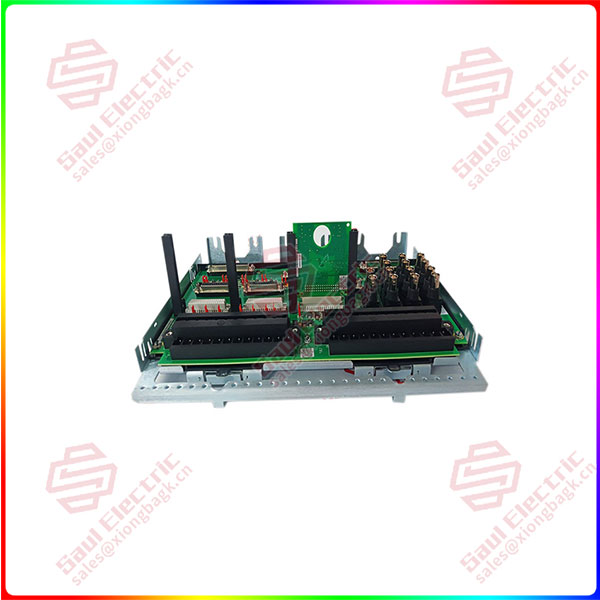

IS230TVBAH2A

The output of the module is optical isolation output, which effectively enhances the security of signal transmission. It is also SIL 2 and SIL 3 compliant with the International Electrotechnical Commission IEC 61508, demonstrating that the module is capable of providing a high level of safety performance in harsh industrial environments.

In terms of technical parameters, the IS230TNRLH1B has an operating temperature range of -40°C to +70°C, which can cover almost all the temperature requirements of industrial environments. In addition, the Module uses the Tricon Communication Module (TCM) interface to communicate, ensuring compatibility with other systems and stability of data transmission.

The main function of the IS230TNRLH1B module is to provide critical digital outputs in safety instrumentation systems to ensure safe operation and shutdown procedures for industrial processes. It is often deployed in applications where reliability, safety and adherence to stringent security standards are critical.

1 Year Warranty

1 Year Warranty