(two) industrial PC

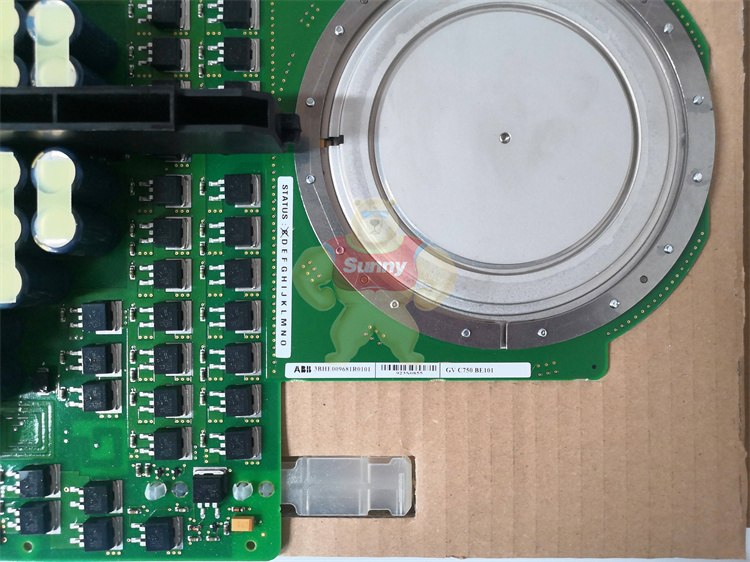

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101Since PC-based controllers are proving to be as good as PLCS and are accepted by both operators and maintainers, one manufacturer after another is adopting PC control solutions for at least some of their production. Pc-based control systems are easy to install and use, have advanced diagnostic functions, provide more flexible options for system integrators, and in the long run, PC control systems have low maintenance costs.

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101Because PLC is controlled by PC the biggest threat, so PLC suppliers feel very uneasy about the application of PC. In fact, they are now part of the PC control “wave.”

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101 In recent years, the industrial PC has obtained unusually fast development in our country. From a worldwide point of view, industrial PC mainly contains two types :IPC and their deformation machine, such as AT96 bus industrial computer. Due to the basic automation and process automation of industrial PC running stability, hot swap and redundancy configuration requirements are very high, the existing IPC has been unable to fully meet the requirements, will gradually withdraw from the field, will be replaced by other industrial computer, and IPC will occupy the management automation layer.

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101

In 2001, the state set up “Industrial control computer-based open control system industrialization” industrial automation major special project, the goal is to develop PC-based control system with independent intellectual property rights, in 3-5 years, occupy 30% (50% of the domestic market, and achieve industrialization.

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101 A few years ago, when “soft PLC” appeared, the industry thought industrial PC will replace PLC. However, today’s industrial PC and? There are two main reasons for not replacing PLC: one is system integration; Another reason is the software operating system Windows NT. A successful PC-based control system should have two points: first, all the work should be done by software on a platform; The second is to provide customers with everything they need.

5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101

It can be predicted that industrial PC and PLC competition will be mainly in high-end applications, its data complex and high equipment integration. Industrial PC can not compete with low – priced micro PLC, which is also the fastest growing part of the PLC market. From the development trend, the future of the control system is likely to exist between industrial PC and PLC, these signs of integration have appeared.

Three, industrial control industry instrument development

Industrial control instrument focuses on the development of main control system device based on fieldbus technology and intelligent instrument, special and special automatic instrument; Expand the service field comprehensively, promote the digitalization, intellectualization and networking of instrument and meter system, complete the transformation of automatic instrument from analog technology to digital technology, and the proportion of digital instrument will reach more than 60% within 5 years; Promote the commercialization of automation software with proprietary copyright.

1 Year Warranty

1 Year Warranty