1.3 Differences between industrial APP and traditional industrial software

Industrial APP is based on industrial Internet platform or industrial software operating system and other platforms, oriented to specific industrial scenarios, to solve specific industrial problems, based on the platform’s technical engine, resources, models and business components, industrial mechanism, technology, knowledge, algorithm and best engineering practices of the code encapsulation of the application. Industrial APP has six typical characteristics:

(1) Industrial APP is the carrier of a certain or some specific industrial technical knowledge software form;

(2) Each industrial APP carries the industrial technical knowledge to solve a specific problem and solve a specific problem;

(3) Industrial APP has single function and relatively small volume;

(4) Industrial APP can not be constrained by tight coupling to a specific application software, and can realize loosely coupled application with other application programs or apps through interface interaction;

(5) The concept, development, application, ecological construction and formation of industrial apps are all carried out based on platforms;

(6) Each industrial APP only solves specific problems. For some complex industrial problems, complex problems can be turned into a series of single problems through problem decomposition, and each single problem is solved by the corresponding industrial APP. Industrial APP is a new form of industrial software.

Compared with traditional industrial software such as CAD, CAE, PLM and MES, its differences mainly include the following five points:

(1) In terms of deployment mode, traditional industrial software is usually deployed locally, while industrial APP is usually deployed in the cloud;

(2) In terms of operation mode, traditional industrial software contains complete industrial software elements, such as technology engine, database, etc., while industrial APP must rely on the technical engine, resources, models provided by the platform to complete development and operation;

(3) In terms of software complexity, traditional industrial software is usually large in volume and complex in operation and use, which requires some professional knowledge to use, while industrial apps are light and easy to operate.

(4) In terms of scalability, traditional industrial software is usually tightly coupled, while industrial APP can not be constrained by tight coupling to a specific application software, and can interact with other applications or apps through interfaces to realize loosely coupled applications;

(5) In terms of application functions, traditional industrial software generally solves general problems at the abstract level, such as CAD software provides highly abstract functional applications oriented to geometric modeling, while industrial apps are used to solve specific industrial problems, such as a certain type of gear design APP can only complete the design of this type of gear. Can not be used for other types of gear design work.

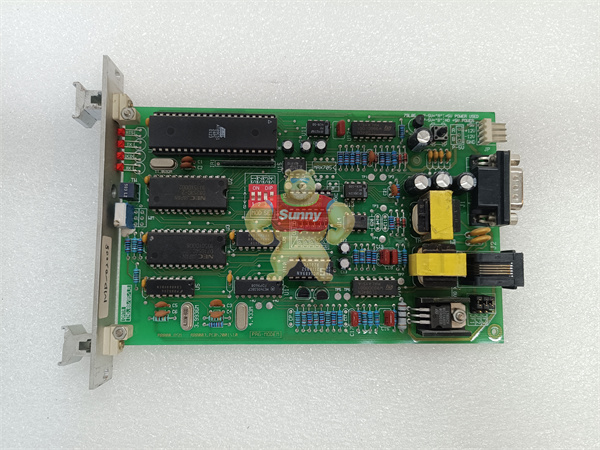

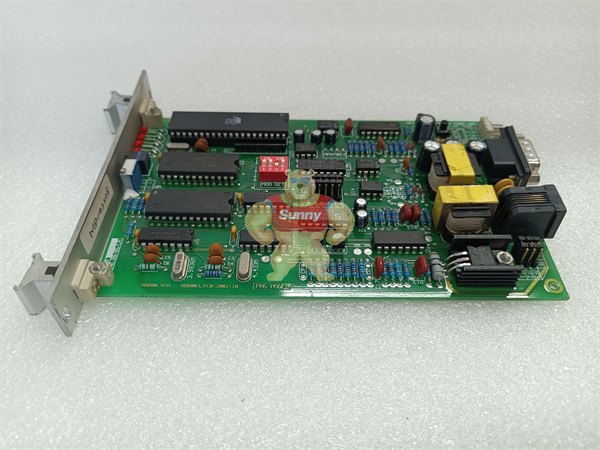

PRG-MODEM

PRG-MODEM

PRG-MODEM

Ii. Why do industrial enterprises want to use industrial Internet platforms?

2.1 Construction of industrial Internet platform is driven by domestic demand in digital and intelligent transformation of industrial enterprises

At the macro level, China’s economic and social development is in a critical period of the transformation of old and new growth drivers. In recent years, the growth of industrial value added gradually slows down. China’s industry is faced with such problems as high input, high energy consumption, high pollution and low efficiency, which seriously restrict the high-quality development of our industrial economy. At the medium level, the Chinese manufacturing industry is at an important stage of development from digitalization and networking to intelligentization. The rapid growth of industrial data requires new data management tools to realize the storage and management of massive data at low cost and high reliability.

The rich data has created the premise for manufacturing enterprises to carry out more refined and precise management. However, the industrial scene is highly complex, and the industry knowledge varies widely. The traditional application innovation mode driven by a few large enterprises is difficult to meet the differentiated needs of different enterprises, so an open application innovation carrier is urgently needed. Through the open invocation of industrial data, industrial knowledge and platform functions, it lowers the threshold of application innovation and realizes the rapid growth of intelligent application. At the micro level, in order to quickly respond to market changes, the parallel organization and resource collaboration between manufacturing enterprises in design, production and other fields are becoming more and more frequent, which requires enterprise design, production and management systems to better support business interaction with other enterprises, which requires a new interactive tool to realize efficient integration between different subjects and different systems. Massive data management, industrial application innovation and deep business collaboration are the main driving forces for the development of industrial Internet platforms.

1 Year Warranty

1 Year Warranty