As one of the manufacturers that actively embrace open automation, Schneider Electric integrates its own deep automation technology and industrial field experience to continuously promote this change. EcoStruxure open automation platform is Schneider Electric’s innovation results in open automation, and is the most mature open automation commercial overall solution.

Since its launch, the EcoStruxure Open automation platform has been updated with more than two versions each year, gradually enriching its features and industry library. According to Yang Hang, the latest EcoStruxure open automation platform V23.0 is further extended to a unified control software platform integrating discrete, mixed and process industry operations to enable more industry customers to improve efficiency. Including enhanced integration with AVEVA system platform, reusing existing application graphics, speeding up system design; Add graphical interface editor for program automation logic design to improve operational efficiency; Open automated human machine interface (HMI) and archiving capabilities, compatible with multiple operating systems, enabling flexible deployment across systems; The EcoStruxure Open Automation Platform V23.0 will further simplify and reduce engineering configuration efforts by 35%.

It can be said that the release of EcoStruxure open automation platform V23.0 has further broken the barrier that control procedures in traditional applications work based on proprietary hardware and cannot run seamlessly in different industrial fields, and through a unified platform and unified source of asset data, it helps different industrial fields to achieve digital continuity of the whole process from design to operation and maintenance.

Schneider Electric is both a beneficiary of open automation technology and an enabler of ecology. Yang Hang said that the technology trend to this node, there is always someone to promote, Schneider Electric is willing to assume such a role to promote the development and popularization of open automation technology.

In order to promote the wider use of IEC61499 in the industry, in addition to launching and continuously enriching the EcoStruxure open automation platform, Schneider Electric also became one of the first industry pioneers to join the Open automation organization UAO (UniversalAutomation.org). Established in 2021, the Open Automation Organization (UAO) is a non-profit international organization dedicated to promoting open automation. Its members include industrial and information manufacturers, integrators, end users and academic institutions, including Schneider Electric, and currently have more than 40 member units, including 4 domestic institutions.

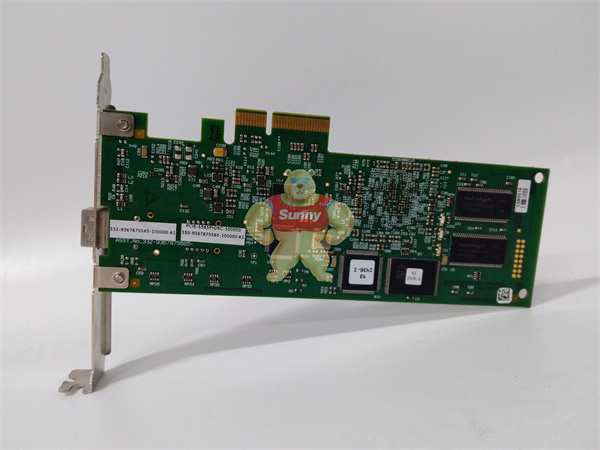

PCIE-5565-PIORC-100A00

PCIE-5565-PIORC-100A00

PCIE-5565-PIORC-100A00

Yang revealed that Schneider Electric is currently working with UAO to promote the concept of standards, openness and common use, to help members of the organization innovate and create interoperable solutions, so as to promote sustainable and lasting positive change in the industry.

Reshaping productivity and efficiency AI has become a key technical support for future industries

The topic of artificial intelligence is now hot, and many people believe that AI will disrupt many fields, including industry. In research and development, manufacturing, management and even innovation, AI may bring great changes to industry.

Schneider Electric is also leveraging cutting-edge technologies such as artificial intelligence to deeply tap the value of big data and achieve highly intelligent industrial automation from the dimensions of quality and yield prediction, predictive maintenance and human-machine collaboration to improve production and operation efficiency. Artificial intelligence has become a key technical support for Schneider Electric’s future industrial strategy.

Yang Hang said that new technologies can only be combined with actual application scenarios to unleash unlimited potential, bringing great improvements in productivity and efficiency, “With the continuous development of artificial intelligence technology, its application in industrial production and maintenance is also increasingly mature.” Schneider Electric is committed to combining AI technology with its own technology and experience in industrial automation and energy management to drive digital transformation and sustainable development in industrial, buildings, data centers, infrastructure and other markets.”

In the industrial sector, based on the deployment of software solutions such as process control, process management, and supply chain management, Schneider Electric introduces AI algorithms to better use real-time data to obtain predictive insights into production systems, help managers make the best decisions, and feed back to the hardware system for adjustment in real time, so as to achieve the optimal efficiency of the system.

Taking Schneider Electric’s China supply chain as an example, AI-based solutions have become a powerful tool for improving production efficiency, controlling costs, and protecting the environment. The AI visual inspection project has successfully covered 10 factories in China, which can detect defects on the surface of products, greatly improve the quality of products, and effectively reduce the waste of resources and time due to product defects. AI laser predictive maintenance projects are based on machine learning algorithms, and through the analysis of large amounts of data, machine failures can be predicted in advance and preventive maintenance can be carried out, thereby improving production efficiency and reducing machine maintenance costs. Over the past year, these AI solutions have generated $4 million in direct cost savings for the factory.

In addition, with the deepening of the application of AI technology in the real industry, more complex non-standard scenarios will emerge, which requires corresponding model support, and the launch of EcoStruxure AI engine is the best solution to this problem.

As Yang says, the industry of the future needs a digital way of thinking – and software and data play an important role in that. Therefore, the software-centric EcoStruxure open automation platform, as well as the data-based EcoStruxure AI engine, will certainly enhance the sustainable development prospects of industrial enterprises.

1 Year Warranty

1 Year Warranty