Description

Overview

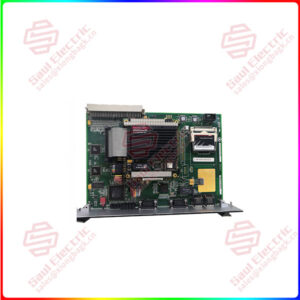

Essential details:0190-24007 Semiconductor board AMAT

As the carrier of semiconductor packaging, the package substrate provides electrical connection, protection, support and heat dissipation for the chip.

Driven by electrical, thermal, size, functionality and cycle cost, the package substrate develops towards thin thickness,

high heat dissipation, fine wiring, high integration and short manufacturing cycle.

The development trend and technical direction of advanced packaging substrates are introduced, and the definition,

application and research status of several advanced packaging substrates such as FCBGA,

coreless packaging substrates and embedded substrates are emphasized.

0190-24007

Sales Manager: Manager He

E-mail number: sales@saulcontrol.com

skypel wechat: +86-18059884797

Mobile phonelwechat: +86-18059884797

QQ:3095989363

Other :0190-24007 Semiconductor board AMAT

0 Introduction

In recent years, in order to meet the needs of high-performance computers,

the new generation of mobile communications, artificial intelligence, automotive electronics and defense equipment and other fields,

electronic products are developing in the direction of high performance and high integration.

In the context of Moore’s law approaching the limit and the high cost of advanced wafer manufacturing process,

advanced packaging technology is becoming more and more important in the industrial chain.

As the core foundation for the design and integration of sub-modules and subsystems and end products in the advanced sealing-test industry,

the advanced substrate is the core carrier to support the huge I/O improvement and SIP (system-level packaging) under the advanced process,

and is the foundation and support of heterogeneous integration technology. In the post-Moore era,

it plays a core supporting role for national key industries and key areas.

1 Year Warranty

1 Year Warranty